Overview

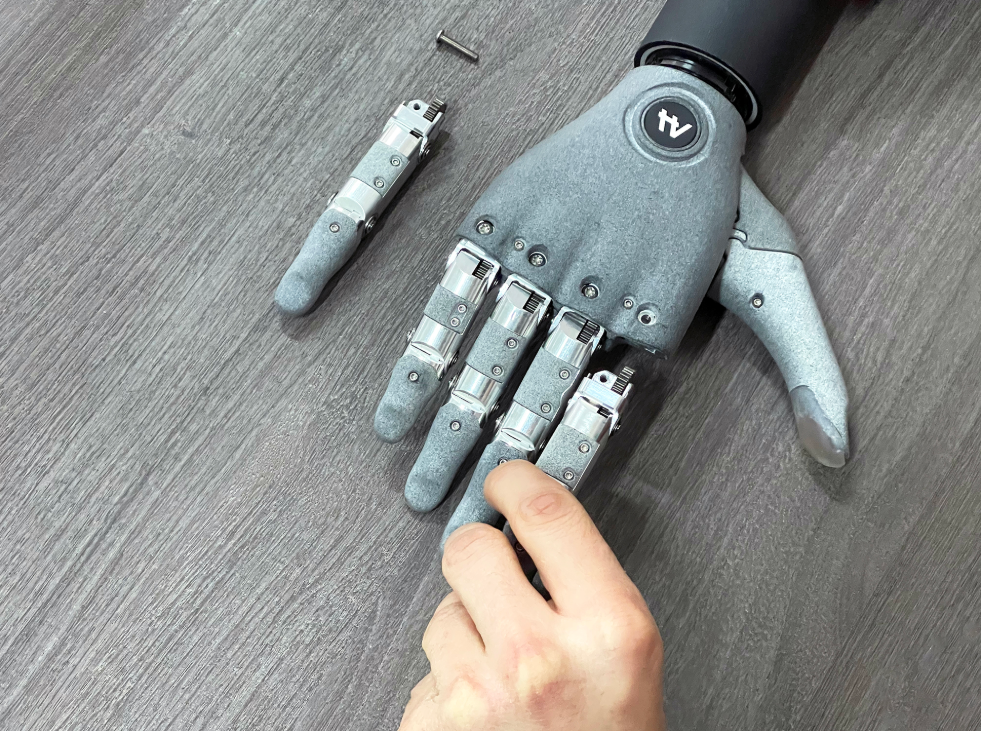

BionIT is an award-winning Italian startup specializing in advanced prosthetic solutions. With a team of biomechanical and medical engineers, they have developed the innovative Adam’s Hand, a cutting-edge prosthetic hand with roboticised grip, designed to improve the lives of amputees.

Challenge

BionIT sought a reliable partner to produce intricate non-printed metal parts for the articulation joints in their prosthetic fingers. These parts required precise CNC machining to ensure optimal functionality and durability. Additionally, BionIT needed a flexible manufacturing solution that could accommodate design iterations and last-minute changes, which are common in the development of prosthetics.

Objectives

-

Secure a reliable supplier for precision CNC machined metal parts for prosthetic finger joints.

-

Ensure flexibility in manufacturing to accommodate design iterations and changes.

-

Explore scalable manufacturing options to meet growing demand and expand product offerings.

Solution

Approach: Quickparts, a leading provider of on-demand manufacturing solutions, partnered with BionIT to address their manufacturing challenges. Quickparts leveraged its expertise in CNC machining and agile manufacturing processes to deliver high-quality parts that met BionIT’s exacting standards.

Technology: Quickparts utilized state-of-the-art CNC machining facilities and advanced software to produce the intricate metal parts for BionIT’s prosthetic fingers.

Processes:

-

-

Phase 1: Initial Production – Quickparts produced an initial order of 80 kits of knuckle joints, with a stipulation that BionIT would receive 30 kits first for testing and design refinement.

-

Phase 2: Design Iteration and Flexibility – Quickparts worked closely with BionIT to accommodate design changes and ensure that the parts met their evolving needs.

-

Phase 3: Exploring Scalable Solutions – Quickparts has recently met with BionIT to discuss scalable manufacturing options, including injection molding and additive manufacturing. These will support BionIT’s growth and expansion plans.

-

Implementation

-

Timeline: The project spans from initial contact in January 2023 to the continued delivery of parts today.

-

Key Actions: Quickparts facilitated last-minute design changes to meet BionIT’s requirements. Following discussions, Quickparts is set to provide inventory on demand for knuckle joints to ensure a steady supply.

-

Team: The project involves close collaboration between BionIT’s engineers and Quickparts’ manufacturing experts.

Results

-

Quickparts’ agile manufacturing processes enabled BionIT to accelerate their product development timeline.

-

The flexibility of Quickparts to respond to design changes quickly and without disrupting production flow has enabled BionIT to optimise their manufacturing costs and achieve a competitive edge.

-

BionIT successfully launched Adam’s Hand in the USA, expanding its reach and impact.

-

BionIT will benefit from Quickparts’ expertise in scalable manufacturing solutions, positioning them for future growth.

-

The collaboration fostered a strong partnership between BionIT and Quickparts, built on trust, flexibility, and a shared commitment to innovation.

Conclusion

Early collaboration between engineering and manufacturing teams is crucial for successful product development. Additionally, embracing agile manufacturing solutions and leveraging a global network of manufacturing partners can empower startups to scale quickly and efficiently.

Quickparts’ partnership with BionIT exemplifies the power of agile manufacturing and collaborative innovation in the field of prosthetics. By delivering high-quality, precision-machined parts and offering scalable manufacturing solutions, Quickparts enabled BionIT to achieve their goals and make a meaningful impact on the lives of amputees.

Quickparts and BionIT continue to explore opportunities for further collaboration, including the development of new prosthetic components and the utilization of Quickparts’ global manufacturing network to support BionIT’s expansion into new markets.