Prototyping & Low-Volume Production for Inventors

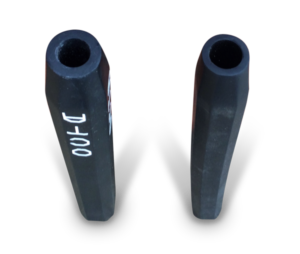

Ronnie Armstrong is, in his words, an amateur inventor, with one copyright and one patent to his name — a board game about baseball and a putter grip, his latest endeavor.

Ronnie wasn’t into golf growing up. He didn’t even attempt the sport until he was in college and played with friends. One told him to go out for the golf team, and he made it, earning a competitive position and playing as the “5th man.” He was hooked, and now, more than 50 years later, he’s still playing and improving his game. Starting with a custom grip for his putter.

Challenge

Ronnie started his quest for the perfect putter grip in his workshop, where he produced several prototypes from wood. Once he got those where he thought they would work, he approached a family member who has a personal 3D printer. They worked together to get the dimensions the way Ronnie wanted them and put a hole in the drawing to allow users to put it on the golf club shaft.

His nephew created a mold and made 2-3 for him out of different materials, including one from hard plastic that is still on one of Ronnie’s putters today. He also worked with a friend who runs a sign company and offered to create a different, two-part prototype from alternate materials.

Once he used the prototypes, he needed more grips and more people to test his design.

Solution

Local manufacturing was important to Ronnie and played a role in who he chose to help produce his putter grip, so Ronnie turned to the Internet to search for a service provider. That’s how he found Quickparts and immediately noticed the Lawrenceburg, TN, facility was close to him.

He needed a good prototype that would be durable enough for strenuous testing on the golf course. He also wanted to submit it to golf regulatory bodies to be approved for use professionally.

He decided to have the grips created with injection molding and ordered 25 each of the medium and large sizes that he felt would appeal to the widest audience.

“Quickparts did a great job with my product,” Ronnie said. “I’m very happy with how it feels and works.” He then gave some to friends to test. “Some really love the grip,” he said, “but I think others just kept them for souvenirs.”

With his patent and the low-volume production he obtained with Quickparts, he believes this grip will ultimately be successful on the market. He has submitted his grips to several retailers and through personal testing has realized the benefits of the design, seeing his putting game improve.

We’re delighted Ronnie chose us to help realize his invention and we wish him the best of luck! If you have a design for a new product or invention that you want to bring to life, connect with our experts or begin your project online now.