SLs Printing

SLS printing is perfect for many of your rapid prototypes, low- and mid-volume productions, and functional testing.

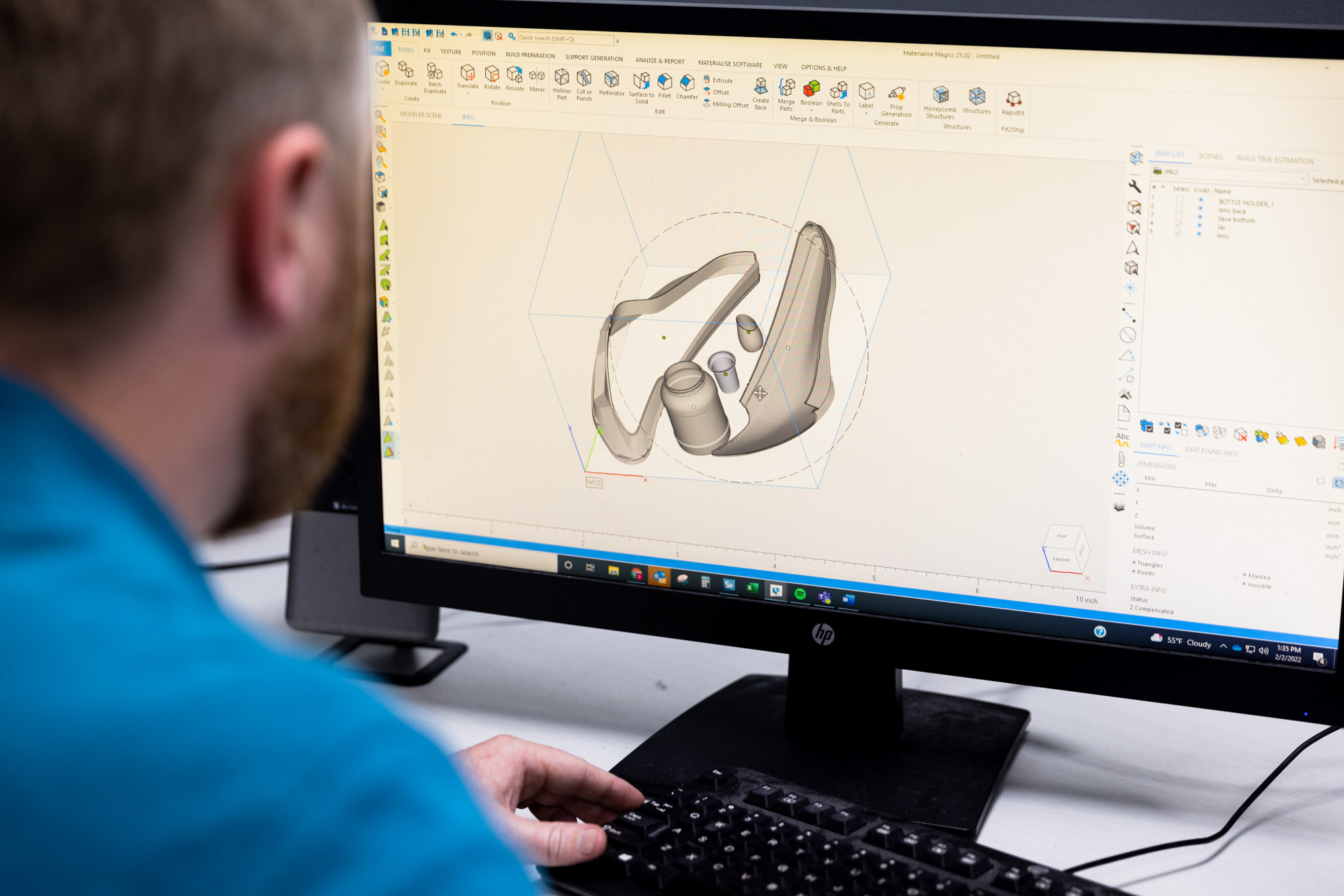

Even highly advanced SLS printing technology isn’t completely reliable if you’re not working with the right team of manufacturing professionals.

Quickparts has the experienced engineers, advanced facilities, and industry know-how to support all your SLS printing needs.

How it Works

SLS printing uses a high-powered laser to fuse small particles of powdered material together into complex and durable 3 dimensional parts.

This laser selectively fuses the powdered material by applying heat and pressure, a process also known as “sintering”.

Let us be your resource to determine which manufacturing process is right for your project.

About Quickparts

Quickparts is a pioneer in the 3D printing world.

We are the originator of a full digital manufacturing platform that delivers on-demand additive and traditional manufacturing services. From rapid prototyping to appearance models and volume production, Quickparts operates the most advanced technology and possesses the expertise to handle any additive manufacturing project.

With facilities stationed around the world, each staffed with experienced engineers laser-focused on meeting your specific requirements as effectively and quickly as possible, you can trust Quickparts with all of your manufacturing needs.