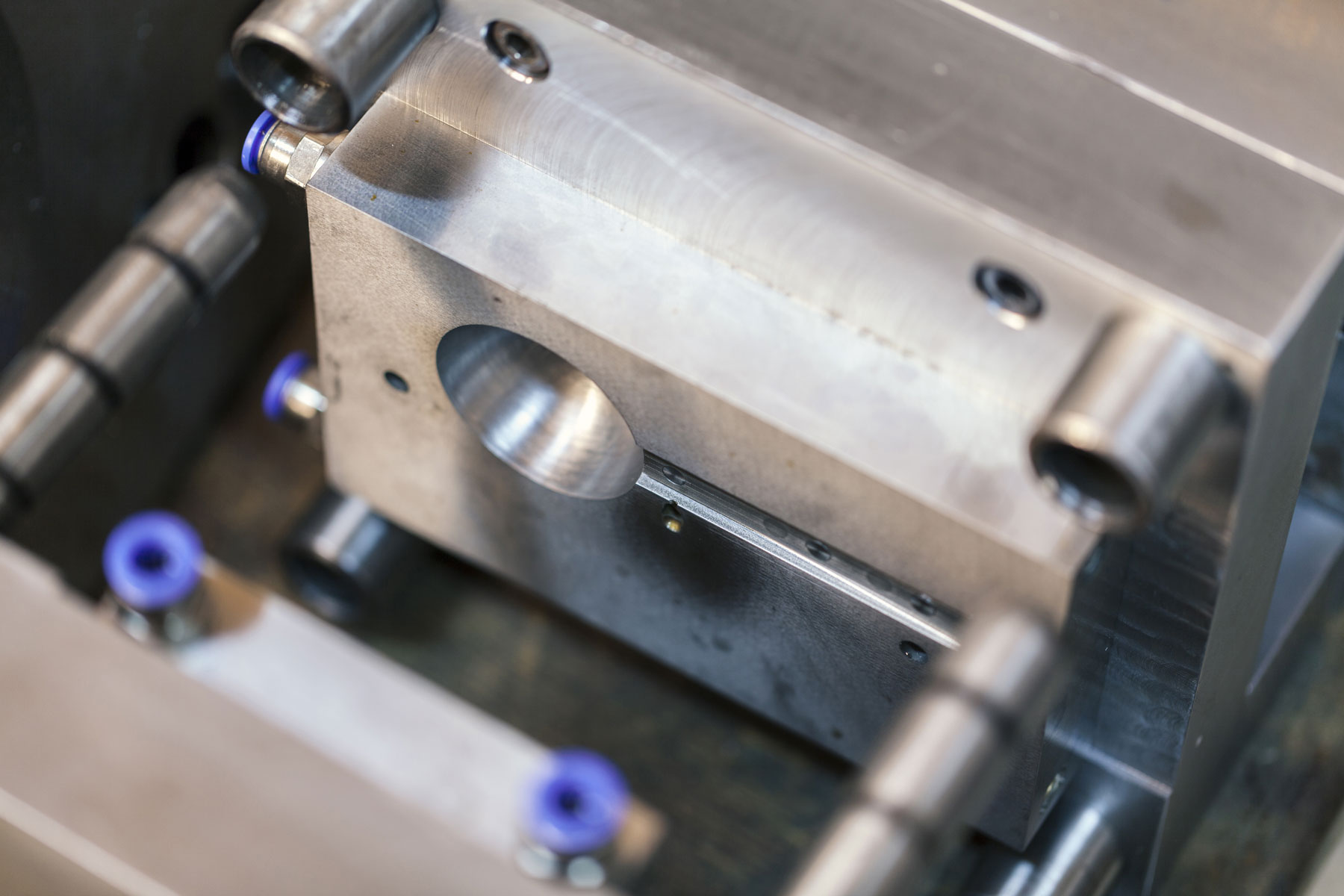

Injection Moulding Tooling, Prototyping, and Parts for Low Volumes

Accelerate your product development cycle with Quickparts’ advanced injection moulding solutions. We provide steel and aluminum tooling to create high-fidelity prototypes, pre-production parts, and series production components manufactured in production-grade materials. This allows for rigorous testing of functionality, durability, and reliability – all before committing to full-scale manufacturing.

- Production-Grade Materials: Match the same materials used in final production runs for accurate performance testing.

- Injection Moulding Design Freedom: Handle most geometries with ease and incorporate overmoulding, insert moulding and component integration to bring your innovative ideas to life without limitations.

- Validate Your Design: Test functionality, durability, reliability, and conduct performance tests with confidence using real production-grade parts.

- Bridge the Gap to Production: Seamlessly transition from prototyping to full-scale production with our bridge-to-production solutions.