In the United Kingdom, manufacturers have steadily shifted away from slow, manual sourcing and now rely on online CNC machining services to achieve faster, more consistent results.

These platforms let engineers upload computer-aided design (CAD) models, receive automated pricing with design-for-manufacture (DFM) feedback, and connect to verified suppliers. Local providers also reduce lead times, avoiding the long shipping delays often seen with overseas sourcing.

This review explains how online CNC machining works, shows leading UK providers, and answers common questions about CNC machining.

How Does Online CNC Machining Work?

Online CNC machining replaces the old back-and-forth quoting process with a straightforward digital workflow. While details vary by provider, most follow the main steps:

- Upload and specify requirements: Engineers upload a CAD file or 2D drawing to a secure portal. They then choose material, quantity, tolerances, and any required surface finishes. Some platforms also allow multiple parts to be uploaded together for assembly quotes.

- Automated quoting and design-for-manufacture feedback: Once the requirements are submitted, the part design is reviewed and prepared for production. Engineers or technicians use CAM software to translate the CAD file into machining instructions, checking for features that might affect production, such as thin walls, sharp corners, or deep pockets. This step ensures the design is practical to manufacture and meets the intended tolerances.

- Order confirmation and production planning: After the design is approved, the job is scheduled with the appropriate machining setup. Factors such as material availability, machine type (for example, 3-axis or 5-axis), and production timeline are considered to align capacity with customer needs. This planning stage ensures the project moves smoothly from design into manufacturing without unnecessary delays.

- Manufacturing and quality checks: The selected shop programmes the machines using computer-aided manufacturing (CAM) software. Common processes include milling, turning, drilling, and boring. Standard machining typically achieves tolerances of ±0.005 inch (±0.127 mm), while specialist precision setups can achieve tolerances of ±0.001 inch (±0.025 mm). Quality checks may involve in-process verification, coordinate measuring machines (CMMs), and material certifications.

- Delivery and support: Once complete, parts are packaged and shipped. UK-based suppliers typically deliver within days, avoiding the long shipping delays and customs issues that come with overseas sourcing. Most platforms also provide tracking information and ongoing customer support.

Best Online CNC Machining Services in the United Kingdom

Online CNC machining providers in the UK cater to different needs, from rapid prototyping and small production runs to high-volume manufacturing. Here’s a list of the best online CNC machining services in the UK.

1. Quickparts

Year founded: 1990

Location: High Wycombe, Buckinghamshire, United Kingdom, as well as global manufacturers and partners

Quickparts delivers CNC machining services that cover projects from single prototypes to full-scale production runs. With a combination of in-house manufacturers and a global supplier network to ensure available capacity and reliable delivery schedules. Its QuickQuote® platform provides instant pricing and lead times, helping engineers move quickly from design to production without delays.

The service operates under ISO 9001:2015 and AS9100D certifications, ensuring compliance with international quality standards. Industries such as aerospace, medical devices, automotive, and electronics depend on Quickparts for consistent, high-quality manufacturing outcomes.

Solutions

- CNC milling: Machines complex geometries and flat surfaces with 3- and 5-axis equipment.

- CNC turning: Produces cylindrical and conical parts such as shafts, bushings, and tubes.

Services

- Additive manufacturing: Supports stereolithography (SLA), selective laser sintering (SLS), direct metal printing (DMP), and fused deposition modeling (FDM) for prototypes and end-use parts.

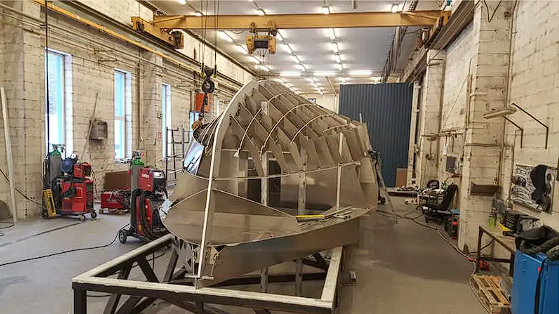

- Sheet metal fabrication: Delivers laser cutting, stamping, bending, and welding in aluminium, steel, brass, and titanium.

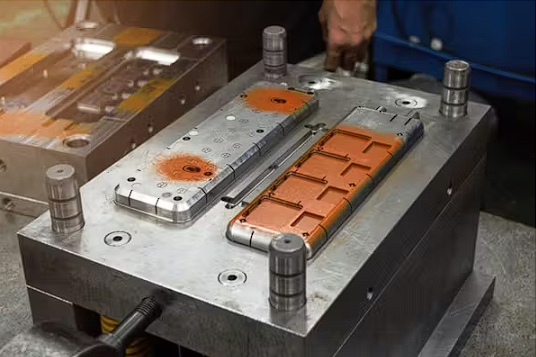

- Injection moulding: Covers rapid prototypes to multi-cavity production, including overmoulding and insert moulding.

- Die casting: Supports aluminium and zinc parts with repeatable surface finishes.

- Vacuum casting: Produces urethane prototypes and master patterns for low-volume moulded parts.

- Rapid prototyping: Accelerates design validation with multiple fast-turn manufacturing options.

2. Fractory

Year founded: 2017

Location: Manchester, UK

Fractory operates an online manufacturing platform that connects engineers and businesses to a network of vetted suppliers across the UK and Europe. The system handles quoting, project management, and quality control, allowing customers to source CNC machining, metal fabrication, and finishing services from a single point of contact. All orders are managed centrally, with supplier capacity and delivery schedules monitored in real time.

Solutions

- CNC milling: Produces precision parts using 3- and 5-axis milling equipment.

- CNC turning: Manufactures cylindrical components, including shafts and bushings.

Services

- Cutting and bending: Delivers laser, tube laser, plasma, flame, and waterjet cutting, as well as metal punching and bending.

- Finishing and assembly: Provides welding, heat treatment, and surface finishing.

- High-volume production: Manages supply chain requirements for large-scale orders.

- Metal casting: Supports casting processes across multiple alloys.

- Project management: Oversees quoting, logistics, and quality control through a centralised system.

3. Geomiq

Year founded: 2017

Location: London, UK

Geomiq operates a digital manufacturing platform that connects engineers with a vetted global supply chain of CNC machining partners. The platform provides instant or 24-hour quotes, automated design for manufacturing checks, and scalable production capacity. Parts are manufactured through a distributed network and verified against ISO 9001:2015 and ISO 13485 quality standards before delivery.

Solutions

- CNC milling: Produces prototypes and production parts using 3-axis, 4-axis, and 5-axis milling machines.

- CNC turning: Manufactures cylindrical components, including shafts, bushings, and threaded parts.

Services

- Injection moulding: Provides tooling and moulded parts for both prototypes and production volumes.

- Sheet metal fabrication: Handles cutting, bending, and forming for enclosures and structural parts.

- 3D printing: Delivers polymer and metal components for prototyping and low-volume production.

- Surface finishing: Applies anodising, plating, powder coating, polishing, and bead blasting across multiple grit levels.

- Assembly and secondary operations: Supports kitting, inspection reports, and integrated post-processing.

4. Get It Made

Year founded: 2011

Location: London, UK

Get It Made provides CNC machining and manufacturing across a range of metals and plastics. Unlike automated instant-quote platforms, the company offers engineer-reviewed quotes tailored to each project. ISO 9001:2015 certification ensures consistent quality, and its partner network spans the UK, China, and Europe. Customers include organisations in aerospace, medical, research, and consumer sectors.

Solutions

- CNC milling: Produces parts with 3-axis, 4-axis, and 5-axis milling for simple and complex geometries.

- CNC turning: Manufactures cylindrical and round-profile components, with Turn & Mill capability for complex features.

- 5-axis machining: Handles advanced parts requiring simultaneous multi-axis toolpaths for precision geometries.

Services

- Plastic injection moulding: Produces moulded parts for both low- and high-volume programmes.

- Aluminium extrusion: Provides custom profiles for prototypes and scaled production.

- 3D printing: Delivers plastic components, prototypes, and short-run batches through additive manufacturing.

- Aluminium die casting: Creates cost-efficient aluminium parts for high-volume applications.

- Sheet metal fabrication: Handles cutting, bending, and forming for enclosures and assemblies.

5. Machining-4u

Year founded: 2013

Location: Rathbone Place, London

Machining-4U runs a UK online marketplace that connects customers directly with machinists. Buyers upload part designs, receive competing CNC quotes, and choose the machinist that best fits their project. The platform enables direct communication, so customers can discuss requirements before production. Machining-4U supports aluminium, steel, stainless steel, brass, and plastics, with machining carried out through CNC milling and CNC turning.

Solutions

- CNC milling: Machines flat surfaces and complex geometries based on customer drawings.

- CNC turning: Produces cylindrical and conical parts such as shafts, adaptors, and couplings.

Services

- Quotation marketplace: Provides multiple machinist quotes for each posted job.

- Secure payment system: Holds funds until customers approve finished parts.

- Material support: Covers aluminium, steel, stainless steel, brass, and plastics.

- SME and individual access: Opens professional machining capacity to smaller businesses and private users.

6. Xometry

Year founded: 2013

Location: Chelmsford, England

Xometry delivers CNC machining services for prototypes and production parts through its global supplier network. Customers upload CAD files and receive pricing, lead times, and manufacturability feedback, with machining carried out by vetted suppliers. They do not operate injection moulding in-house; instead, they manage tool and part production through a vetted network of external manufacturing partners worldwide.

Solutions

- CNC milling: Produces parts with 3-axis, 4-axis, and 5-axis milling machines for simple and complex geometries.

- CNC turning: Manufactures cylindrical and round-profile components including shafts, bushings, and threaded parts.

- CNC routing: Machines large-format plastic and metal sheets for prototyping and production.

- High-volume CNC machining: Provides repeat production capacity for scaled manufacturing programmes.

Services

- Injection moulding: Delivers moulded plastic parts for prototypes and production programmes.

- Die casting: Produces metal parts in high volume using aluminium, zinc, and other alloys.

- Sheet metal fabrication: Includes laser cutting, bending, stamping, and welding.

- 3D printing: Offers polymer and metal additive manufacturing across multiple processes.

- Assembly and secondary operations: Provides kitting, inspection, finishing, and part integration.

Choosing the Best Online CNC Machining Service Company in the UK

Selecting the right CNC machining partner is about more than just cost. The best suppliers provide consistency from prototype to production, reduce risks through design feedback, and maintain reliable lead times. They also offer a broad range of material options and scalable capacity, ensuring projects stay on schedule regardless of their size or complexity.

Quickparts delivers CNC machining services built around speed, precision, and flexibility. Its approach combines engineering support, quality assurance, and a global supplier network to meet both urgent prototyping needs and long-term production programs. By centralising design input, manufacturing, and logistics, Quickparts helps businesses maintain control and minimise disruptions throughout the process.

Getting started is simple. Upload your CAD files through the QuickQuote platform to receive fast, transparent pricing along with design-for-manufacturability insights. With these tools, you can evaluate options early, avoid costly adjustments, and move forward with confidence.

Ready to begin your CNC machining project?

Get your free quote from Quickparts today.

Online CNC Machining Services FAQs

What industries use CNC machining?

Manufacturers across multiple sectors rely on CNC machining when precision and repeatability are critical. Automotive companies machine engine housings, suspension components, and brackets that must withstand heavy loads. Aerospace uses it for turbine blades, landing gear, and lightweight structural parts where accuracy is non-negotiable.

In the medical field, CNC produces implants, surgical tools, and diagnostic devices from stainless steel and titanium for compliance and safety. Industrial machinery, robotics, and automation systems depend on CNC for gears, frames, and custom fittings. Electronics and consumer product manufacturers also use CNC to create enclosures, housings, and small-batch prototypes.

How accurate is CNC machining?

CNC machining offers high accuracy, with standard machines holding tolerances around ±0.01 mm to ±0.025 mm. Advanced systems can achieve sub-micron precision, down to ±0.0025 mm, for specialised parts.

Accuracy is defined by tolerances, the allowable deviation from the intended geometry, and is influenced by factors such as machine calibration, tooling quality, material properties, and shop conditions.

What are the different types of CNC machining?

Different types of CNC machining include:

- CNC milling

- CNC turning

- Multi-axis machining (4-axis and 5-axis)

- Swiss machining

- Electrical discharge machining

- CNC routing

- CNC waterjet cutting