Traditional Manufacturing

As a global manufacturing leader, we are equipped to handle any project.

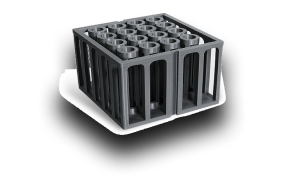

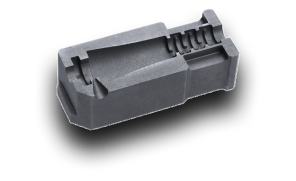

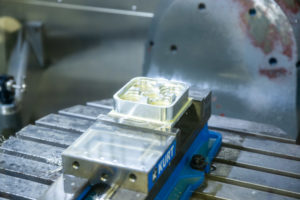

This includes all your traditional manufacturing, from Injection Mold Tooling to CNC to Sheet Metal Manufacturing, and more.

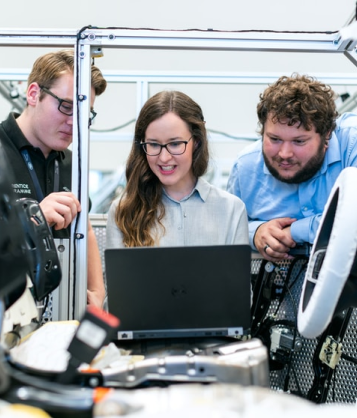

Our experienced engineers and global network of facilities produces the parts you need, when and where you need them.

How it Works

Traditional manufacturing differs from additive manufacturing in that it is a subtractive method. Instead of adding materials to created a part or prototype, tools are used to remove material until the part is created.

Material availability is an advantage for traditional manufacturing, as your parts can be created using a vast array of metals, plastics, or alloys.

Our experienced team of engineers have the expertise to deliver advanced traditional manufacturing projects.

Quickparts efficiently fulfills millions of manufacturing orders annually.

Let us be your resource to determine which manufacturing process is right for your project.

About Quickparts

Quickparts is a pioneer in the 3D printing world.

We are the originator of a full digital manufacturing platform that delivers on-demand additive and traditional manufacturing services. From rapid prototyping to appearance models and volume production, Quickparts operates the most advanced technology and possesses the expertise to handle any additive manufacturing project.

With facilities stationed around the world, each staffed with experienced engineers laser-focused on meeting your specific requirements as effectively and quickly as possible, you can trust Quickparts with all of your manufacturing needs.

Get Started

You’re seconds away from starting your Quickparts project.