Traditional Manufacturing

As a global manufacturing leader, we are equipped to handle any project.

This includes all your traditional manufacturing, from Injection Mold Tooling to CNC to Sheet Metal Manufacturing, and more.

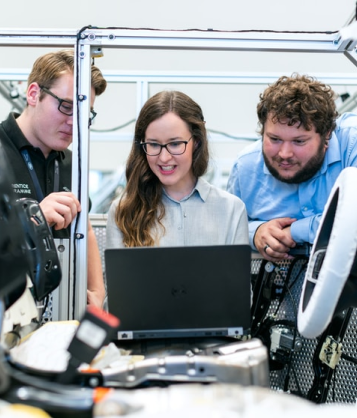

Our experienced engineers and global network of facilities produces the parts you need, when and where you need them.

How it Works

Traditional manufacturing differs from additive manufacturing in that it is a subtractive method. Instead of adding materials to created a part or prototype, tools are used to remove material until the part is created.

Material availability is an advantage for traditional manufacturing, as your parts can be created using a vast array of metals, plastics, or alloys.

Our experienced team of engineers have the expertise to deliver advanced traditional manufacturing projects.

Quickparts efficiently fulfills millions of manufacturing orders annually.

Let us be your resource to determine which manufacturing process is right for your project.

About Quickparts

Quickparts is a pioneer in the 3D printing world.

We are the originator of a full digital manufacturing platform that delivers on-demand additive and traditional manufacturing services. From rapid prototyping to appearance models and volume production, Quickparts operates the most advanced technology and possesses the expertise to handle any additive manufacturing project.

With facilities stationed around the world, each staffed with experienced engineers laser-focused on meeting your specific requirements as effectively and quickly as possible, you can trust Quickparts with all of your manufacturing needs.

Get Started

You’re seconds away from starting your Quickparts project.

Traditional Manufacturing Services- We Have The Best Manufacturers

Additive manufacturing can be very advantageous to designing prototypes specifically because subtractive manufacturing is the perfect option for some applications. This is where you can rely on our traditional manufacturing service providers. Partner with us and get the best traditional prototype manufacturing solutions from our team.

Why choose us for traditional manufacturing services?

Affordable Solutions

The manufacturing landscape is dynamic. Quickparts’ team has found a high value in combining traditional and modern manufacturing methods. From full-production runs to highly accurate prototypes, our team provides you with comprehensive solutions. Our traditional production system helps create parts flawlessly.

Fast and responsive

We have highly experienced manufacturers in the traditional manufacturing industry. So, we are highly skilled in providing you with the fastest solution as per your requirements.

When do you need our traditional manufacturing services?

Although additive manufacturing processes facilitate ongoing customization trends, traditional manufacturing is acceptable. The major goal of every business is to produce quality products. Conventional methods enable our customers to move forward while relying on our manufacturing partners.

You can consult our manufacturers to choose between modern and traditional manufacturing processes.

Our traditional manufacturing solutions-

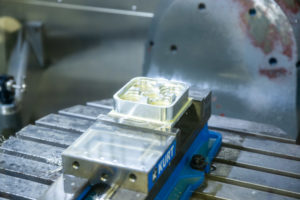

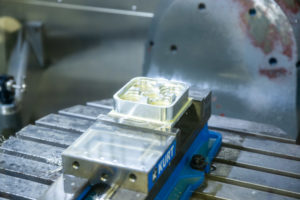

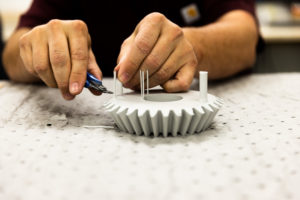

CNC machining– We conduct this subtractive process using 3 to 5-axis milling machines. We also use different types of cutting tools and remove some materials from metal and solid plastic blocks. You can choose our CNC milling services to design different geometric patterns.

We are also efficient in the CNC turning process, as it is best for manufacturing round components. For instance, we prefer this method for designing tubes and bars.

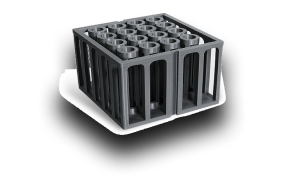

Injection molding– Our team helps you with thermoplastic, thermoset silicone, and metal injection molding services. We can provide you with different options, like over molding and insert molding. Overmolding is a way to create parts from various materials. It is also best for developing chemically-bonded parts. Insert molding is almost like over molding through the substrate may not be plastic. Most commonly, we create sharp handheld tools with this method. Our clients have chosen insert molding services to design clips, fasteners, and bushings.

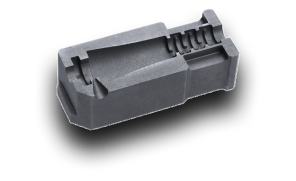

Urethane casting– You can choose this traditional manufacturing process for different purposes. For instance, a cast urethane prototype is used for consumer tests. We will design parts of various materials, strengths, and sizes. Some companies also prefer urethane casting for designing their 3D logos.

Urethane casting involves no costly tooling. Instead, we apply the manufacturing method for designing geometrically intricate parts. During this process, we pour the resin into the silicone mold. Then, we left it to cure the material in a chamber and develop a solid part.

Are you ready to submit your traditional manufacturing project? Traditional Manufacturing service providers, like Quickparts, are the best solution for you! We are highly skilled machinists providing the best services at the most affordable rate. Our team works closely with every customer to identify the technology and materials best for industrial production needs.