Global supply chain uncertainty and shifting cost structures are changing how manufacturers approach production planning. Speed-to-market, flexibility, and proximity to your production partner are no longer optional. Without them, projects face delays, higher shipping costs, communication breakdowns, and longer lead times.

For UK manufacturers who need consistent part quality at scale, injection moulding remains one of the most dependable production methods. Whether you’re building medical components or durable consumer parts, the right supplier can help reduce lead times and lower defect rates.

Choosing the wrong injection moulding partner in the UK can lead to missed deadlines, inconsistent part quality, and unnecessary design rework. In this article, you’ll learn everything about the best injection moulding companies in the UK, including who they serve, what they offer, and how to find the right fit based on your project.

How Does Custom Injection Moulding Work?

Custom injection moulding is the process of producing plastic parts specifically designed for a single application. These are not standard parts pulled from existing tooling—each job starts with a unique design, dedicated mould, and selected materials based on what the part needs to do in real-world use. It’s used when off-the-shelf solutions won’t meet the requirements, for example, when a medical device needs a biocompatible part, or when a structural clip in an automotive assembly must meet exacting tolerances and survive repeated use. It’s a practical, repeatable process for producing high-quality plastic parts at medium to high volumes, with the precision and consistency manufacturers rely on.

The first step is part design. You define exactly what the part needs to look like and how it should perform, including dimensions, strength, material type, finish, and any special features like threads or mounting points.

Once the design is ready, a toolmaker builds a custom mould, usually from hardened steel or aluminium. This tool has two halves that form the shape of the part, along with channels to guide the molten plastic, and mechanisms to eject the finished part after moulding.

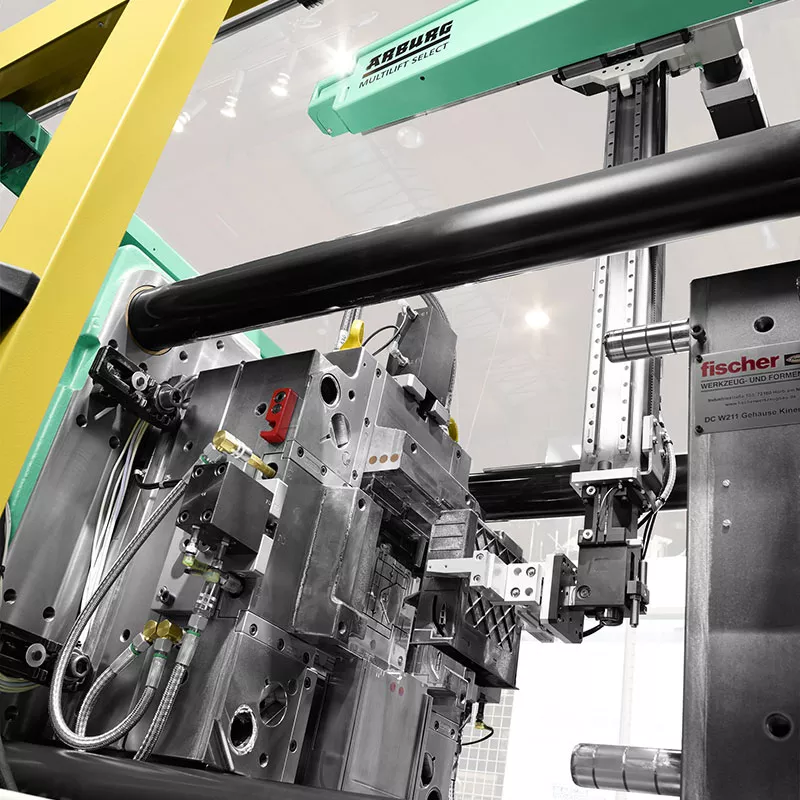

The mould is then installed into an injection moulding machine. Plastic pellets are poured into a hopper, where a motor-driven screw feeds them forward through a heated barrel. As the pellets move, they melt from both friction and external heaters to become a thick, flowable liquid.

That molten plastic is then injected into the mould cavity at high pressure. The goal is to fill every detail of the mould quickly and completely before the material starts to cool. The mold should stay closed until the plastic solidifies.

After cooling, the mould opens and ejector pins push out the finished part. The process repeats—often producing parts in cycle times as short as a few seconds, depending on part size and complexity.

Every variable, including the type of plastic, injection pressure, cooling time, and even the surface finish, can be tuned for that specific part. If needed, the process can also include insert moulding (where plastic is moulded around a metal or threaded component) or overmoulding (where multiple layers of material are combined).

How to Evaluate Injection Moulding Suppliers

Choosing the right injection moulding supplier can directly affect your product timeline, cost structure, and part reliability. Speed and part quality should be standard—but what matters more is the supplier’s ability to function as a long-term manufacturing partner.

Here are some key areas to consider when evaluating injection moulding suppliers:

- Customer-driven collaboration: Work with suppliers who listen before they quote. They should ask targeted questions about your application, timeline, and constraints, then tailor their recommendations to fit your needs, not force you into a standard workflow.

- Speed and precision: Choose a supplier that can move quickly without sacrificing quality. Look for clear timelines, rapid tooling options, and defined quality standards, alongside real examples of delivering tight tolerances on short lead times.

- Iteration: Evaluate whether the supplier supports iteration, not just prototyping. They should offer DFM input, handle mid-process design changes, and scale with your needs as the design evolves, without restarting from scratch each time.

- Transparent communication: Expect regular updates from a dedicated contact who understands your project inside and out. A responsive supplier should flag risks early, confirm requirements before tooling, and keep you informed from quote to delivery.

- Customisation capabilities: Work with suppliers who can adapt their process to your part, not the other way around. That means handling complex geometries, supporting features like undercuts, inserts, and multi-material moulding, and offering tooling built specifically for your design. A supplier should be able to show examples of non-standard work and clearly explain how they’d approach yours.

- Design consultation: Look for suppliers who review your computer-aided design (CAD) files with a manufacturing lens. This includes checking for common issues like thin walls, sharp internal corners, inadequate draft angles, and unrealistic tolerances, before any tooling begins. A supplier that provides detailed design-for-manufacturing feedback will help you avoid unnecessary rework and ensure your part is mouldable at scale.

- Tooling capabilities and lead times: Evaluate what types of tooling the supplier offers, prototype vs. production, aluminium vs. steel, soft vs. hard tools, and whether they can meet your timeline without cutting corners. A capable supplier will be transparent about what’s achievable within your schedule and budget, and explain tradeoffs (e.g., shorter lead time vs. tool life).

- Scalability from prototype to production: Ensure the supplier is equipped for both small batches and high volumes. You may start with a few hundred parts, but you need to scale to tens of thousands. The same supplier should support this transition without requiring a full retool or change in process. Ask how they handle tooling upgrades or increased part demand over time.

- Material flexibility and knowledge: Choose a supplier that stocks a broad range of thermoplastics and can help you select the right one based on your mechanical, thermal, and cosmetic requirements. They should also be willing to work with customer-supplied materials if your application needs something specific. Suppliers who understand how material choice impacts shrinkage, surface finish, and tolerance will help you avoid production delays or failed assemblies.

- Achievable tolerances and repeatability: Ask what tolerances they routinely achieve and what’s considered realistic for your part size and geometry. A supplier that quotes ultra-tight tolerances without discussing your material or tool type may be overpromising. A reliable partner will tell you what’s possible, what’s practical, and where you may need to adjust your design.

- Manufacturing footprint and in-house capabilities: Look for suppliers who do their own tooling and moulding in-house, especially if they have facilities near your region. This reduces lead times, avoids customs issues, and gives you more control over revisions and quality checks. If they outsource key steps, expect delays and less visibility into production issues.

- Communication and project management: Expect a single point of contact who owns your project from design through delivery. You shouldn’t have to chase down updates or repeat instructions across departments. A responsive supplier will keep you informed on tooling status, production schedules, and any issues before they affect delivery.

- Advanced technical capabilities: If your part involves complex features, like threaded inserts, flexible overmoulds, or multi-cavity tools, confirm that the supplier has experience with those exact needs. Not all moulders are equipped to build or maintain complex tools, and learning that mid-project can stall your timeline.

- Inspection and quality control standards: Find out how the supplier manages part inspection. This includes whether they use standard measurement reports, check critical dimensions during production, and track batch consistency. Quality should be built into their process, not just handled at the end.

- Long-term fit: A reliable injection moulding partner should help you reduce long-term costs, not just quote you a cheap part. The right supplier will work with you to avoid design mistakes, catch manufacturability issues early, and scale with your needs as your product grows. That kind of support matters more than a slightly lower quote or a marginally faster ship date.

Best Injection Moulding Companies in the UK

The United Kingdom has various injection moulding companies offering different capabilities, tooling options, and production scales. Here’s some of the best injection moulding companies in the UK.

1. Quickparts

Year founded: 1990

Location: High Wycombe, Buckinghamshire, United Kingdom. Also operates globally.

Quickparts provides end-to-end injection moulding services, from early-stage prototyping through to high-volume production. They produce all tooling in-house and support multiple tooling classes, allowing customers to match cost and tool life to the needs of their project.

They offer a design-for-manufacturing (DFM) review as standard, helping to catch geometry, tolerance, or material issues before tooling begins. This reduces rework, shortens lead times, and keeps projects on schedule.

Their process supports a variety of moulding techniques, including insert moulding, overmoulding, multi-cavity, and stack moulds. Customers can use off-the-shelf materials or supply their own, depending on specific application requirements.

Quickparts supports localized supply chain efficiency by producing tools and parts in-house at regional facilities, helping reduce shipping time, customs delays, and overall lead times. Their process is built to manage the entire product lifecycle, from initial prototyping to full-scale production, without restrictions on part complexity or volume. Quickparts U.K. facility holds ISO 9001:2015, EN 9100:2018, ISO 27001:2022, and AS9100 (UK) certifications.

Injection moulding solutions:

- Quick moulded parts: Support low-volume needs with short lead times and prototype-grade tooling.

- Prototyping: Provide early-stage parts using production-grade materials for design validation.

- Production: Deliver high-volume parts with long-life tooling, consistent accuracy, and material flexibility.

- Overmoulding: Enable multi-material parts by moulding plastic over a base component.

- Stack moulding: Produce multiple part layers in one cycle using stacked mould faces.

- Hot runner moulds: Reduce cycle time and material waste with heated runner systems.

- Insert moulding: Integrate metal or other inserts directly into moulded plastic parts.

- Highly intricate tooling: Support complex part geometries with tight dimensional tolerances.

- Multi-cavitation tooling: Increase part output by producing multiple identical parts per cycle.

Other manufacturing and production services:

- CNC machining: Produce precise metal and plastic parts with tight tolerances and high repeatability.

- Stereolithography (SLA): Create detailed prototypes with smooth surface finishes using liquid resin and UV light.

- Selective laser sintering (SLS): Build functional nylon parts layer by layer without the need for support structures.

- Vacuum casting: Replicate production-quality parts quickly using silicone moulds and polyurethane resins.

- Investment casting patterns: Produce wax or resin patterns used in high-precision metal casting processes.

- Direct metal printing (DMP): 3D print metal components directly from CAD using fine metal powders and laser melting.

- Sheet metal fabrication: Cut, bend, and assemble metal sheets into brackets, enclosures, and structural parts.

- Die casting: Form metal parts in high volumes using reusable moulds and pressure-injected molten alloy.

- Rapid prototyping: Quickly produce models or test parts to evaluate form, fit, and function before full production.

2. Adreco Plastics

Year founded: 1977

Location: Milton Keynes, Buckinghamshire, United Kingdom

Adreco Plastics is a UK-based injection moulding and toolmaking company. The company supports industries including automotive, medical & hygiene, retail, construction, beverage, defence, agriculture, lighting, and packaging.

Adreco holds ISO 9001:2015 and ISO 14001 accreditation and is JOSCAR registered to serve regulated sectors such as aerospace, defence, and medical. It offers cleanroom assembly, packaging, and tool servicing within its UK site.

Injection moulding solutions:

- Insert moulding and overmoulding: Use twin-shot and unscrewing tooling to produce multi-material components such as closures and seals.

- Regulated sector production: Operate under ISO 9001 and ISO 14001 systems with JOSCAR registration for defence and aerospace components.

Other manufacturing and production services:

- Precision toolmaking and mould repair: Design, build, and service tools onsite.

- Assembly and packaging services: Perform unit assembly and cleanroom packaging.

3. Bowles & Walker

Year founded: 2002

Location: Watton, Norfolk, United Kingdom

Bowles & Walker operates an in‑house plastic injection moulding and toolmaking facility that supports product design, prototyping (including 3D printing), tool design, and full-scale production.

Their services cover industries such as automotive, medical, retail, electronics, building & construction, agriculture, and consumer goods. The company holds ISO 9001:2015 certification and employs sustainable practices, including recycling plastic waste and using solar and wind energy at its site.

Injection moulding solutions:

- Full-service injection moulding: Handle design, toolmaking, prototyping, and production in a single facility.

- In‑house mould tooling and servicing: Maintain full control over tool lifecycle, enabling re-use or transfer of tools as needed.

- Produce parts under ISO 9001 quality systems: Ensure consistency in production using certified quality management practices.

Other manufacturing and production services:

- Design consultancy and prototyping services: Include product design support and 3D printed prototypes before full tooling begins.

- Tool repair and refurbishment: Maintain and modify mould tools onsite to support repeat production or design changes.

4. BSA Mouldings

Year founded: 1991

Location: King’s Lynn, Norfolk, United Kingdom

BSA Mouldings operates a plastic injection moulding plant, handling product design, tooling, prototyping, and full-scale production. The company serves markets including automotive, medical, electronics, consumer goods, retail, construction, and agriculture..

BSA also provides in-mould decoration, CAD-based design support, and uses tooling and manufacturing automation to handle parts across weight and complexity ranges.

Injection moulding solutions:

- Product design and DFM consultation: Review part designs early to enhance manufacturability and reduce assembly steps.

- Full-service injection moulding: Run tooling, moulding, short-run prototyping, and volume production in-house.

- Precision and high-volume moulding: Produce both small and large parts with consistent tolerances using high-capacity machines.

- In-mould decoration (IMD): Integrates decoration during moulding to avoid secondary labelling or printing.

Other manufacturing and production services:

- 3D design and prototyping services: Offer CAD and 3D printed prototypes before full tool development.

- Assembly and packaging services: Assemble and pack finished parts for distribution.

- Storage and distribution services: Provide warehouse storage and global shipping support.

5. Cameron-Price

Year founded: 1960

Location: Birmingham, West Midlands, United Kingdom

Cameron-Price offers full in-house support across project planning, product development, tooling management, and moulding processes.

They hold IATF 16949:2016 and ISO 9001:2015 certifications, supporting production for sectors including automotive, industrial, electronics, hygiene, and consumer products. Cameron-Price operates 24 hours a day, five days a week and manages both tool commissioning and part validation internally.

Injection moulding solutions:

- Custom plastic injection moulding: Manufacture moulded components to customer-defined specifications.

- Tooling and project validation: Manage development, trials, and sign-off of tooling before production.

- Material procurement and traceability: Source and control production materials in-house.

Other manufacturing and production services:

- Product development and design support: Assist with early-stage development and design for manufacture.

- Post-moulding operations: Provide assembly, finishing, and value-added part processing.

- Packaging and logistics services: Manage packing and supply chain coordination for finished parts.

6. Labone Castleside

Year founded: 1968

Location: Castleside, Consett, County Durham, United Kingdom

Labone Castleside manufactures plastic injection mouldings and supports customers from CAD models through to mass production, working alongside toolmakers and using Mouldflow analysis to optimise part and tool design.

It holds ISO 9001:2015 and IATF 16949:2016 certification and applies VDA 6.3 and AIAG quality standards across automotive and other sectors. The company uses online customer portals for RFQs, engineering change requests, and PPAP submissions to coordinate project delivery.

Injection moulding solutions:

- Plastic injection moulding and assembly: Manufacture and deliver moulded parts combined with product assembly per customer CAD data and project requirements.

- Mouldflow-aided design optimisation: Use Mouldflow analysis prior to toolmaking to reduce design iteration and tool correction loops.

Other manufacturing and production services:

- Project management and customer portals: Manage RFQs, engineering changes, PPAP documentation, and order tracking through online systems.

- Packaging and logistics planning: Design packing methods and labelling workflows, including barcoded solutions and verification processes.

7. OGM Moulding Innovation

Year founded: 1962

Location: Yarnton, Oxfordshire and Hengoed, South Wales, United Kingdom

OGM delivers plastic injection moulding, toolmaking, and component assembly and serves industries including medical and healthcare, electronics, utilities, and general industrial sectors.

The company holds ISO 9001:2015, ISO 14001:2015, and ISO 13485:2016 certifications and features Class 7 (10,000) cleanroom assembly for medical-grade manufacturing.

Injection moulding solutions:

- Plastic injection moulding services: Handle full-scale moulding from concept through production at both UK sites.

- Design consultancy and prototyping: Advise on manufacturability and validate prototypes before tooling begins.

- Additive manufacturing for conformal cooling inserts: Use metal 3D printing to enhance tool efficiency and part quality.

- Cleanroom assembly under ISO 13485: Manufacture and assemble medical components within Class 7 cleanroom environments.

- Component assembly and box‑build: Combine injection‑moulded parts with electronics and wiring into finished assemblies.

Other manufacturing and production services:

- Metal additive manufacturing: Produce mould inserts and tooling components using 3D metal printing technology.

- Project management support: Assign dedicated teams to oversee sourcing, project tracking, and new product introduction phases.

- Validation and inspection services: Conduct part validation and control processes to meet regulatory and quality standards.

- Reshoring consultancy: Assist companies in relocating production back to the UK to reduce lead times and simplify logistics.

8. Omega Plastics

Year founded: 1998

Location: Gateshead & Washington, Tyne and Wear, United Kingdom

Omega Plastics Group provides plastic injection moulding, tooling, assembly, and dispatch services. The company operates under ISO 9001 and ISO 14001 certification and delivers turnkey solutions from concept through to product deployment.

Omega serves the automotive, medical, consumer, industrial, aerospace, and defence sectors through low- to high-volume moulding services. Their facilities include tooling, plastic moulding, and value-added assembly operations under the same quality system.

Injection moulding solutions:

- Low- to high-volume injection moulding: Handle a range of production volumes with in-house tooling and moulding capabilities.

- Turnkey project delivery: Manage tooling, moulding, assembly, and dispatch within one supplier workflow.

- Insert moulding and overmoulding: Use specialized processes to produce multi-material components.

- Operate under certified quality frameworks: Produce parts under ISO 9001 and ISO 14001 systems to meet industry requirements.

Other manufacturing and production services:

- Mould tool manufacturing: Design and build tools in-house to support direct production needs.

- Process control and quality inspection: Maintain in-process inspection and automated quality tracking across all stages of production.

9. Patterson & Rothwell

Year founded: 1982

Location: Royton, Oldham, Lancashire, United Kingdom

Patterson & Rothwell operates plastic injection moulding and toolmaking services, covering the full scope from product design through production. The company supports industries such as automotive, consumer products, building, and horticulture through moulded components. It manages product design, tool design, toolmaking, and high-volume production in-house using various thermoplastic materials.

The facility holds certification to IATF 16949 and ISO 9001 quality standards, supporting regulated manufacturing processes.

Injection moulding solutions:

- Full-service injection moulding: Handle product design, tool design, toolmaking, and production in-house.

- Design-to-production continuity: Maintain control across tool development, validation, and production launch phases.

- Quality standards: Implement IATF 16949 and ISO 9001 systems to ensure consistent specification compliance.

Other manufacturing and production services:

- Part design and DFM support: Assist early-stage design reviews and optimisation before tooling.

- Tooling services and maintenance: Design and manufacture mould tools onsite, and perform tool servicing when required.

- Packaging and logistics coordination: Handle final assembly, packaging, and logistical delivery support.

10. Pentagon Plastics Group

Year founded: 1972

Location: Horsham, West Sussex, United Kingdom

Pentagon Plastics provides a full turnkey injection moulding service, from design and development to tooling, moulding, and post‑production support. The company supports regulated industries such as medical, aerospace, defence, marine, electrical, and security, processing engineering-grade thermoplastics to close tolerances.

It holds ISO 9001:2015 certification across both tooling and moulding divisions, with daily quality control procedures including First Article Inspections and in-process quality plans for each part.

Injection moulding solutions:

- Comprehensive injection moulding services: Manage design for manufacture (DFM), toolmaking, mould trials, and volume production in-house.

- Design validation and prototyping: Offer DFM review, tooling trials, and material evaluation before full-scale production.

- Tooling division onsite: Build, service, refurbish, and repair single, multi‑cavity, and hot‑runner mould tools at the same location.

- Post moulding operations: Provide finishing, inserting, waxing, painting, and assembly services directly after moulding.

Other manufacturing and production services:

- Material support and process control: Manage material procurement, ERP integration, and production traceability across the supply chain.

- Project and quality management: Assign dedicated teams for contract review, quality inspections.

11. Rutland Plastics

Year founded: 1956

Location: Oakham, Rutland, United Kingdom

Rutland Plastics provides end-to-end plastic injection moulding services, including design for manufacture, tooling, prototyping, moulding, and finishing. The company serves sectors such as automotive, medical, construction, consumer goods, utilities, and electronics via engineering-grade thermoplastics and electrofusion fittings.

They hold ISO 9001:2015, ISO 13485:2016, and ISO 14001:2015 certifications and maintain Investors in People and Sedex registrations to support quality and sustainability initiatives.

Injection moulding solutions:

- Gas-assisted injection moulding: Integrate gas injection to reduce material use and improve part appearance.

- Insert and outsert moulding: enable insertion of metallic parts or multi-material assemblies during moulding.

Other manufacturing and production services:

- 3D printing and rapid prototyping: deliver prototypes, jigs, and tooling components using in-house additive technologies.

- Machining, assembly, and finishing: include sonic welding, heat staking, gluing, and full sub-assembly operations.

- Warehousing and call-off support: hold stock for bulk manufacturing and permit scheduled call-off logistics.

12. Tex Plastics

Year founded: 1986

Location: Derby and Barnstaple, United Kingdom

Tex Plastics manufactures high-spec injection moulded components for sectors including medical, electronics, construction, and interiors, operating from two UK sites in Derby and Barnstaple. They provide full-service support, including DFM, prototyping, tooling, validation, and scalable production.

Injection moulding solutions:

- Precision injection moulding: Manufacture multi-shot and micro plastic parts for high-spec sectors.

- Cleanroom injection moulding: Produce non-sterile medical parts in ISO Class 7 environments.

- Low-volume injection moulding: Support validation, short runs, and pilot production.

Other manufacturing and production services:

- Design-for-manufacture and prototyping: Provide early-stage design support, tooling simulations, and prototyping.

- Assembly and post-mould operations: Include welding, finishing, kitting, JIT delivery, and Kanban.

- Maintain quality control systems: Ensure traceability, inspection, and quality assurance across production.

Partner with the Best Injection Moulder in the UK

When it comes to injection moulding, the partner you choose can directly affect your timelines, tooling costs, and the overall quality of your parts. That’s why working with a single supplier that handles both prototyping and production under one roof can make all the difference. It cuts down on communication gaps, reduces the risk of delays, and helps keep your project moving forward without unnecessary rework.

But there’s more to a good partner than just convenience.

The best UK injection moulding vendors offer tooling flexibility, tight tolerance capabilities, and clear engineering feedback—before production ever begins. That kind of support can prevent surprises and save serious time and money.

Quickparts is one of those companies. With in-house tooling and moulding, global partners, and local production sites, they bring speed, quality, and control together in one process. From the moment you submit your design to final delivery, a dedicated team keeps you in the loop. That means full visibility, fewer headaches, and no last-minute scrambles to solve problems.

Quickparts is known for working with challenging geometries without asking customers to redesign around manufacturing limitations. Whether you’re launching a prototype or ramping up to full production, the same team supports you every step of the way—making transitions smoother and helping you avoid costly rework.

With over 35 years of experience, their process is predictable, efficient, and built around getting your parts done right—and on time.

Want to see how it could work for you?

Get a QuickQuote from Quickparts and connect with a specialist today.