DMP: 3D METAL PRINTING

Direct metal printing: The ideal solution for high-quality, complex metal parts.

With extensive experience in direct metal printing and a team of skilled operators, dedicated project managers, and efficient logistics, Quickparts ensures your project’s success from start to finish.

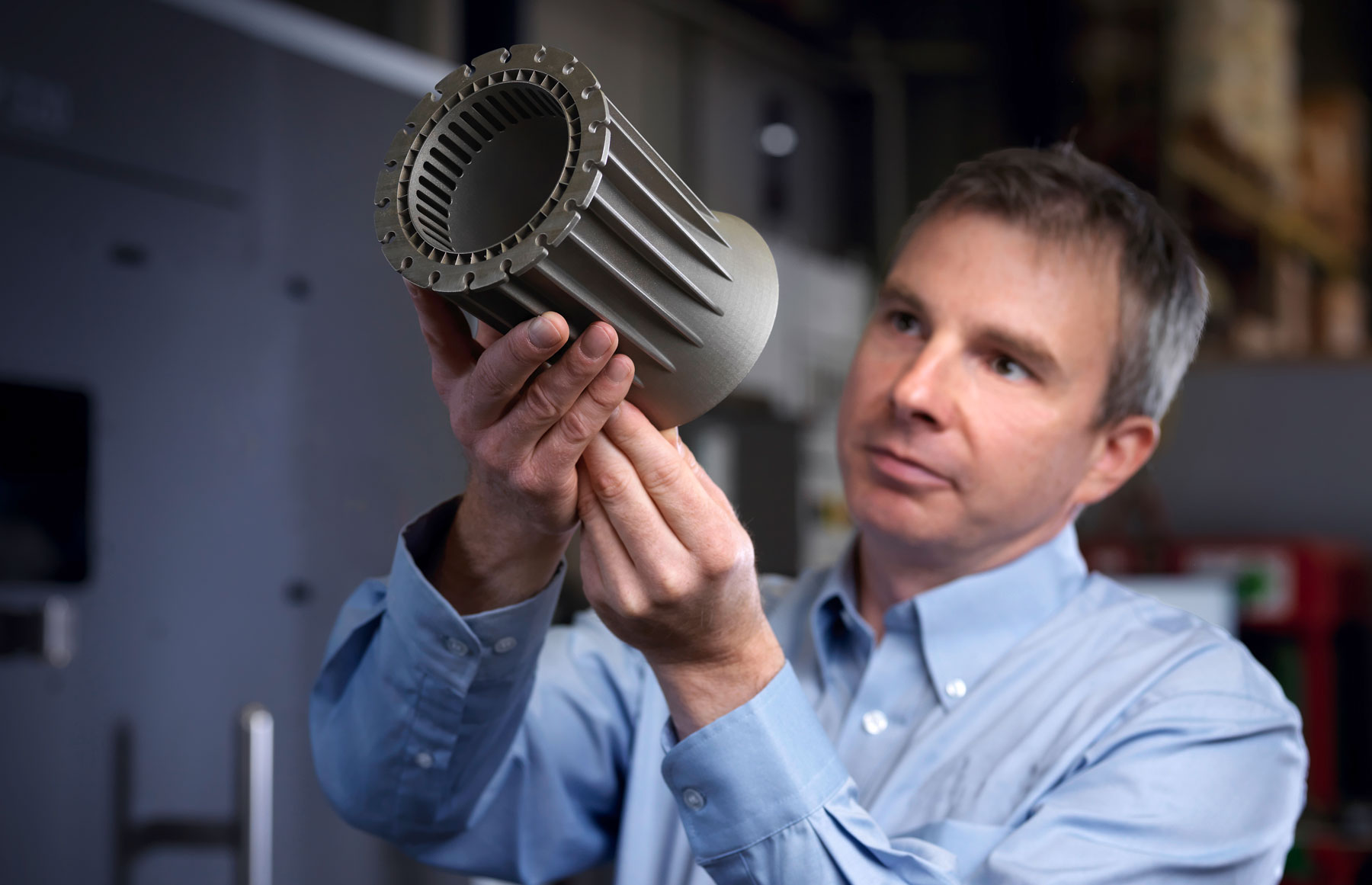

Backed by years of experience in 3D metal printing, Quickparts has honed its expertise across diverse applications, from demanding motorsport environments to intricate industrial components. Our skilled team and streamlined processes ensure your direct metal printing production is in capable hands.

How our 3D Metal Printing service works

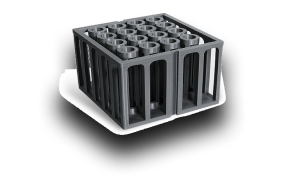

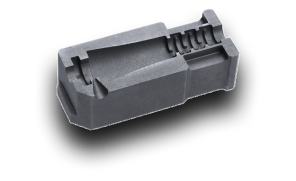

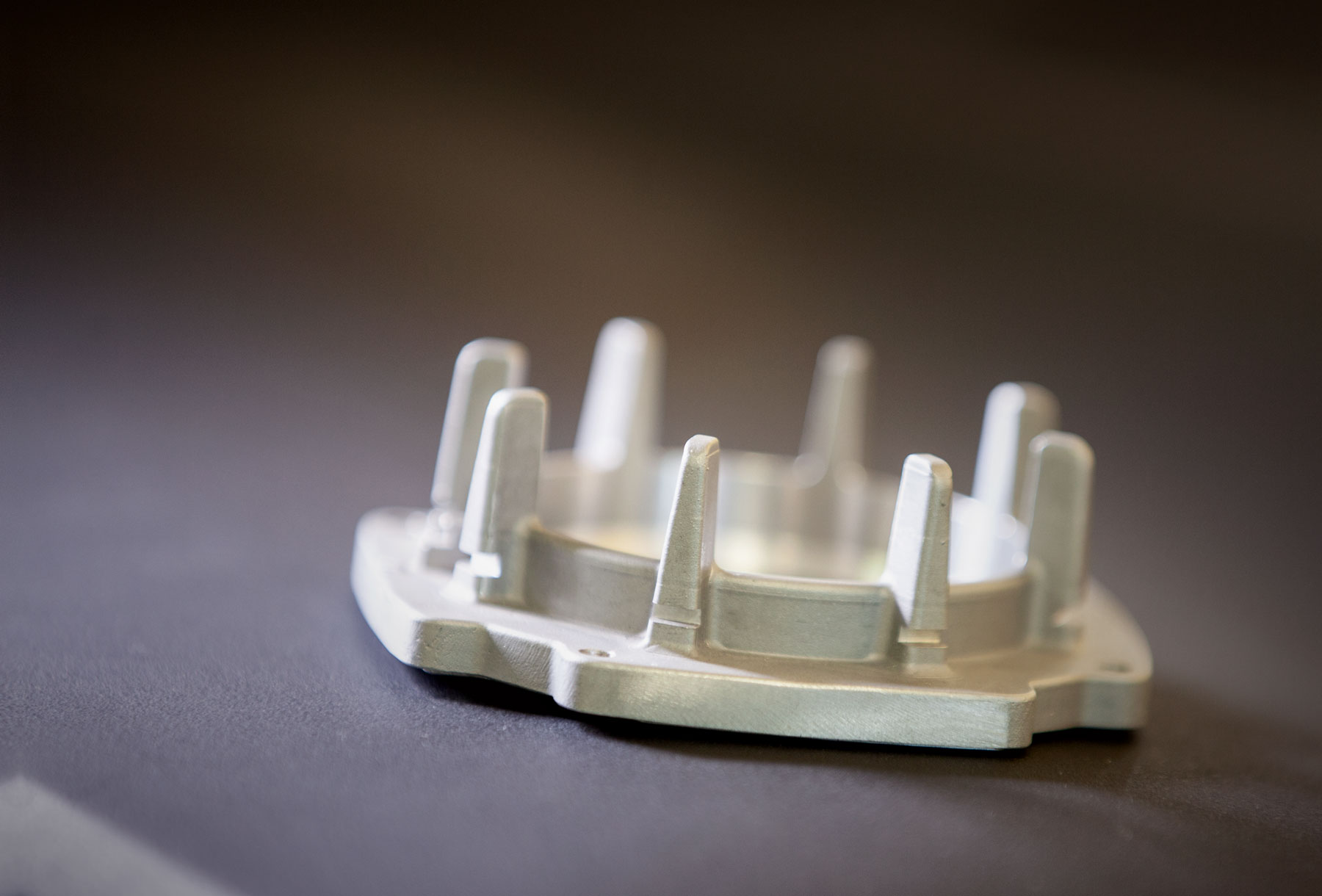

Direct Metal Printing is an additive manufacturing technology that builds high-quality, complex metal parts from 3D CAD data.

A high-precision laser is directed to metal powder particles to selectively build up thin horizontal metal layers, one after the other.

Let us be your resource to determine which manufacturing process is right for your project.

About Quickparts

Quickparts is a pioneer in the 3D printing world.

We are the originator of a full digital manufacturing platform that delivers on-demand additive and traditional manufacturing services. From rapid prototyping to appearance models and volume production, Quickparts operates the most advanced technology and possesses the expertise to handle any additive manufacturing project.

With facilities stationed around the world, each staffed with experienced engineers laser-focused on meeting your specific requirements as effectively and quickly as possible, you can trust Quickparts with all of your manufacturing needs.

Get Started

You’re seconds away from starting your Quickparts project.