CNC Machining SERVICES

Seamlessly scale from prototype to production with quality CNC machining services.

Quality assured CNC parts for low to high volume production runs: Our global network assures capacity for on-time delivery, every time.

Why Quickparts?

- Perfect Precision – 3 and 5-axis machining with tolerances to ±0.001”

- Instant Quoting – Get pricing in seconds with our updated customer portal, QuickQuote®

- Unconstrained Quantities, Size and Complexity – supporting you from prototyping to low, mid and high volume manufacturing

- Pre-production Review – Our standard ‘design for manufacturing’ review helps to mitigate potential issues, ensuring your parts meet your expectations

- Experience – Over 25 years of industry expertise. Our skilled CNC operators have an average of 10 years experience

- Outstanding Customer Service – More than 4000 satisfied customers

From concept to production: CNC machining in metals and polymers, including:

|

|

|

How it Works

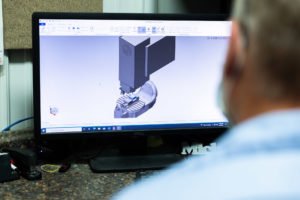

CNC machining refers to cutting material with a computer numerical control machine. Similar to additive manufacturing techniques, the CNC machining process translates 3D CAD models into CNC machine data. The CNC machine then produces your part in the material you intend to use in production.

CNC Machining is a broad term encompassing various computer-controlled processes used to shape materials, including milling, turning, drilling, and more. Quickparts offers a range of CNC services, including milling and turning.

In CNC milling, the workpiece remains stationary while the rotating cutting tool moves along multiple axes to carve out the desired shape. This makes it ideal for creating complex geometries and flat surfaces.

In CNC turning, the workpiece rotates on a lathe while a stationary cutting tool removes material to create cylindrical or conical shapes. This process is perfect for producing symmetrical parts like shafts and tubes.

Quickparts has the right CNC machining options for your metal or plastic part needs.

Learn more details and the history of this process in our article “What is CNC Machining?”

Let us be your resource to determine which manufacturing process is right for your project.

Get Started

You’re seconds away from starting your Quickparts project.