Quickparts is excited to announce an exclusive promotion for our Detroit, MI manufacturing facility’s injection mold and tooling capabilities. For a limited time, we’re offering Free Tooling—valued up to $5,000.

Take advantage of this opportunity to kickstart your production and save on tooling costs!

Special Offer Details | Injection Mold Tooling

- Free Tooling Offer: Get free injection mold prototype tooling (up to a $5,000 credit value), with an initial minimum parts order of 500.

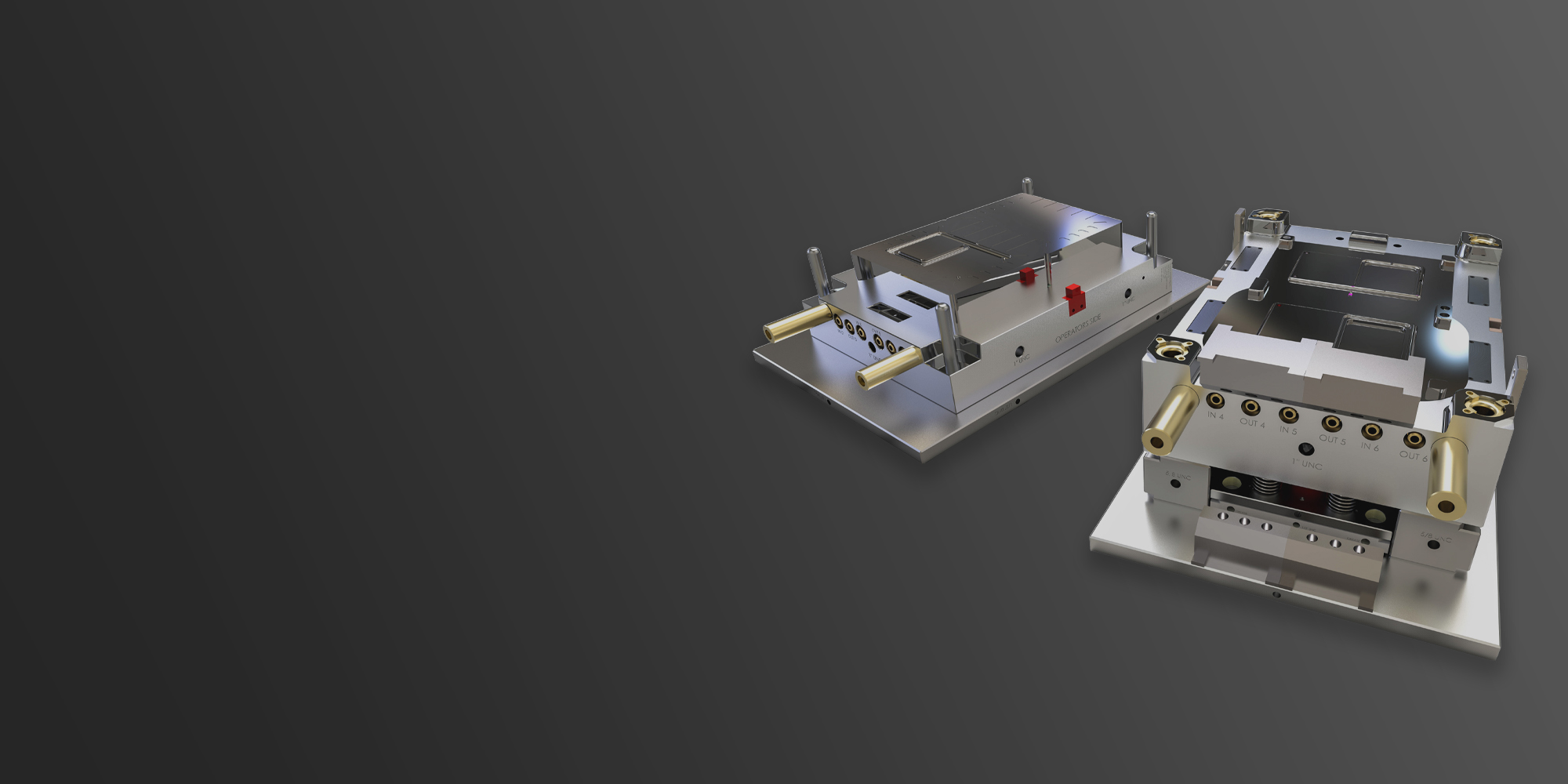

- Tooling Details: Ships in 2-6 weeks after PEG approval, no geometry limitations, tool life up to 2,500 parts, max part size up to 9″ x 9″ x 4″. See terms and conditions for more details.

- Order Deadline: Offer valid until December 15th, 2024. Secure your free tooling by acting fast!

Why Choose Quickparts for Injection Molding?

Midwest Made, World-Class Quality: Experience exceptional efficiency and quality with our domestic injection tool and molding services in Detroit, MI.

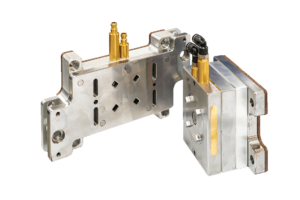

Injection Mold Tooling Experts: Our facility specializes in aluminum tooling, which is designed to offer fast turnaround times and cost-effective solutions.

Precision and Customization: Whether you need rapid prototyping injection molding or custom aluminum mold fabrication, our team ensures your tooling needs are met with precision.

Rapid Production: We’re experts in short-run injection molding tools, allowing for flexible production that caters to both prototyping and low-volume manufacturing.

Learn more about all of our injection molding services.

*Terms & Conditions: The “Midwest Made – Free Tooling” campaign is effective from Monday, October 14th, 2024, at 4:00 AM UTC to Monday, December 16th, 2024, at 4:00 AM UTC. The offer is applicable only to prototype tools (aluminum tools) with a maximum part size of 9” x 9” x 4”. Maximum credit value of $5,000 USD. A minimum initial order of 500 units is required with the tool order. Offer applies exclusively to parts produced in “Quickparts Standard Materials” and is valid only for standard lead times. Only one order per company is permitted. Customers must register with a valid company email address. This offer is only valid in the United States. The tool will remain in our facility for a period of 24 months. Standard tooling terms and exclusions apply. The promotion has no cash value and cannot be rolled over or combined with other promotions. Other restrictions may apply as determined by Quickparts Acquisition, LLC. This offer is subject to change without notice and may be withdrawn at any time. These terms and conditions shall be governed by the laws of the state in which Quickparts Acquisition, LLC, is located. For questions regarding this promotion, please contact Quickparts Acquisition, LLC. By participating in this campaign, you agree to abide by these terms and conditions.

Aluminum Tooling vs Steel Tooling – Why Aluminum?

Our prototype aluminum tooling offers several benefits over traditional steel tools:

- Faster Turnaround: Aluminum molds have significantly reduced lead times, ideal for rapid prototyping.

- Cost-Effective: Aluminum tooling is an affordable alternative suitable for low-volume and prototype projects.

- High-Quality: Achieve the precision and quality needed for plastic parts while reducing upfront costs.

Why Choose Quickparts for Production Injection Molding

The Detroit production facility is at the forefront of modern injection molding technologies and is equipped to handle prototype and short-run production with exceptional efficiency. Our commitment to rapid tooling and flexible production solutions ensures you meet your project timelines without compromising quality.

Don’t miss out on this chance to boost your production capabilities with free injection mold tooling. Our experienced team is ready to assist you every step of the way, from tool design services to fast production turnaround.

Ready to take your production to the next level? Contact us today to secure your free tooling and discuss your custom mold tooling needs. Let Quickparts be your partner in efficient, cost-effective injection molding solutions.