Why Use Undercuts When Designing For Plastic Injection Molding?

Undercuts achieve complex plastic part designs for the injection molding process. For example, overmolding and insert molding.

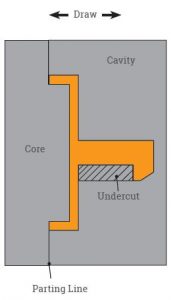

An undercut is any indentation or protrusion that prohibits part ejection from a mold. It is a feature that the cavity and core cannot capture alone. It is die-locked which prevents the part from being ejected from the cavity.

Purpose of Undercuts In Plastic Injection Molding

Some of the more common ways to use undercuts:

- Create interlocking or snap and latch features. This allows for clamshell or housing designs to come together for quick and easy assembly

- Capture side holes or ports for wiring,and button features

- Capture vertical threads and barb fittings. Barb fittings are typically used in medical device products

- Core out thick sections not captured by the core and cavity alone. This prevents the possibility for sink and warp

- Provide threaded and custom inserts that are not in the line of draw. The insert itself can sometimes create undercuts

A thorough DFM will identify problematic areas within the undercut features. Therefore, it’s best to design it as you intend it and to keep the functionality of your design.

DOWNLOAD: Designing for Manufacturability Ebook

Medical plastic parts

Undercuts are commonly used in medical parts. At left, is a medical part with some key features. The internal threads on this part use a side action to unscrew from the part. Continue threads throughout the entire interior of the part. This will prevent the interior hand load from being die-locked.

The space between the inlet ports require a special undercut called a core-out. Core-outs keep wall thickness even and are a planned aspect of the design. Barbs are complex undercuts for medical parts that are necessary for tubing. Most manufacturers will mold this so that the barb is parallel to the parting line. Quickparts uses a complex undercut that includes a pin assembly. This is to allow for venting and capturing the barbs perpendicular to the parting line. The venting will prevent gas trapping and air burning which creates short shots at the tip of the barb feature.

Consumer electronics

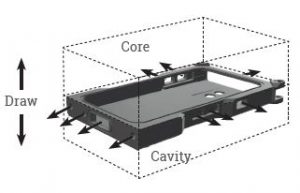

Below is a cell phone housing that contains many undercuts. All the holes located on the side of the housing, for example. These functional features include buttons, port holes and hinges. However, each undercut adds to the complexity of the mold.

There are also some recessed areas that we call internal undercuts. These are areas inside the part that cannot be captured from outside the part. Internal undercuts can be the most difficult for a manufacturer to capture. Considerations must be made to allow enough space for their removal.

Design requirements

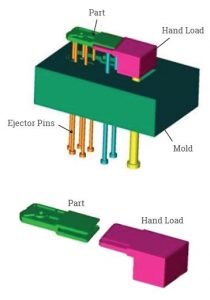

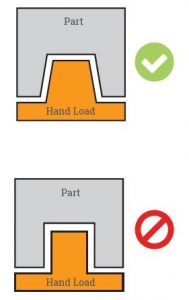

Consider the following requirements to help ensure success when designing undercuts. Only part features captured by hand loads or side actions have design requirements. The first requirement is space. Design your feature (button, port hole, etc.) with enough space to remove the hand load without obstruction. Otherwise, the hand load will be die-locked. This will make it impossible to remove.

Next, design your part so the molder can pinch the hand load or action with the cavity or core. This will result in a tight shut-off for reducing parting line flash. Finally, add enough draft to your undercut to ease removal from the mold.

Challenges with undercuts

One challenge with molding parts with underucts is a lack of draft. Non-drafted areas are difficlut to remove. Demolding parts with insufficient draft will make it difficult to remove the side action manually. Alternatively, the hand load can be coated with nickel-plating. This will allow for a more non-abrasive connection between the part and hand load. Thereby making removal easier. Certain materials can also be challenging when incorporating undercut features. Some materials, like glass filled plastics, are more difficult to pull from the mold. In general, the harder the material, the harder the pull. So, it is essential to put as much draft as possible when using these harder materials.

Finally, cosmetic surfaces with undercuts are difficult to maintain. This is due to increase parting line exposure from the hand load. One solution is to reduce the amount of parting lines on the outside. This is done with an internal undercut.

Undercut best practices

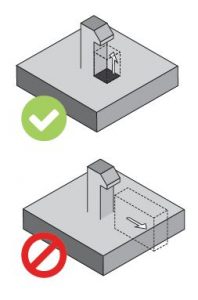

Undercuts add complexity cost to the mold. This is why we recommend eliminating them when possible. To achieve this, design part features that are perpendicular to the draw line.

We use hand loads for speed and time to market. This also depends on the part geometry or whether or not it is an external or internal undercut. The auto-slide is implemented based on a longer cycle production to reduce overall per part cost. If speed is essential, we use manual hand loads.

Interested in obtaining more advice? Reach a Technical Engineer at contact@quickparts.com, or call +1 931-766-7290