Production Tooling and Parts with Unwavering Quality

Power up your production with Quickparts’ high-volume injection molding solutions. We excel at efficiently manufacturing large quantities of complex plastic parts – from 2,500 units to over 1,000,000 – ensuring consistent quality throughout.

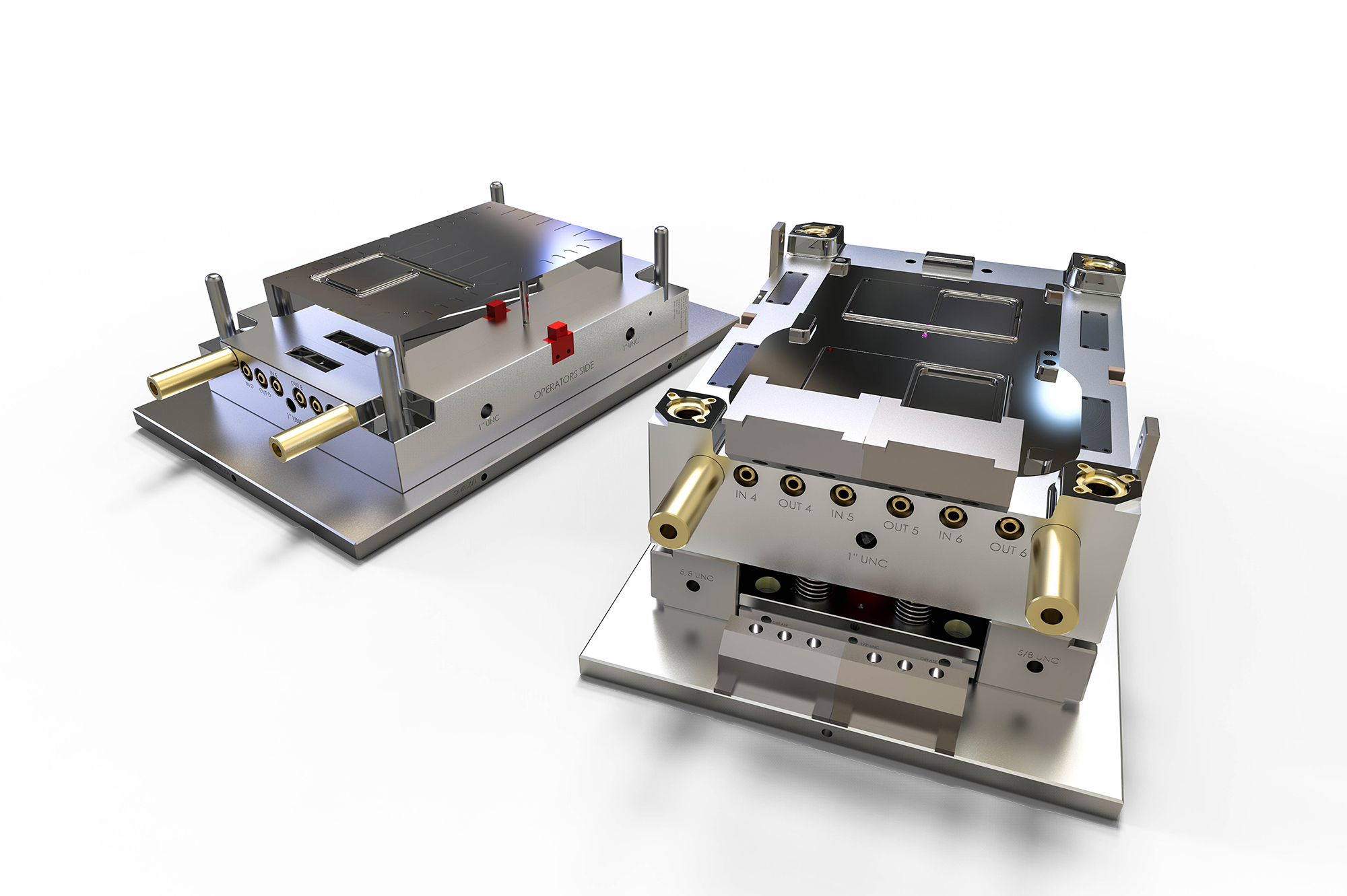

Built for Durability

Robust Production Runs: Seamlessly scale up your production with our reliable high-volume capabilities.

Pre-Hardened Steel Molds: Our durable, pre-hardened steel molds and inserts ensure long-lasting performance and consistent part quality across large batches.

Uncompromising Quality

Collaborative Quality Control: Partner with our team to define and agree upon stringent quality protocols specific to your project.

Production-Grade Precision: We manufacture parts to your exact, pre-agreed specifications, adhering to 100% production standards established before production commences.

Customer-Owned Tooling: Retain complete ownership of your mold and inserts. Tool storage is offered for 36 months.

Flexibility and Control

Maximum Build Size: Our machines accommodate large parts, with a maximum build volume of 1,500 x 1,000 x 350mm, or 60″ x 40″ x 14″.

Material Choice: Select from a vast array of customer-specified materials, or provide your own for complete control.

Guaranteed Success

Quality Assurance: Quickparts guarantees the quality of both parts and tooling, ensuring production meets your stringent standards.

Streamlined Process: Receive a comprehensive Design for Manufacture analysis within 3 days, setting the stage for a smooth production run. PEG within 2 -3 days of tool completion. Parts ship 3 to 8 weeks after customer agreements are signed.

Technical Specifications

Maximum Part Size |

Tolerances |

Wall Thickness |

Radii |

| 1,500 x 1,000 x 350mm/60″ x 40″ x 14″ | According to customers’ 2D drawing | Material dependent, typically minimum 0.6 mm/0.024″ | According to customers’ 2D drawing and CAD3D |

Ready to unlock the power of high-volume injection molding?

Upload your CAD files or contact us today for a free quote and discuss your specific project requirements. Quickparts is your trusted partner for efficient, high-quality plastic production.

ABOUT QUICKPARTS: One of the World’s Leading Injection Molding Suppliers

We are the originator of a full digital manufacturing platform that delivers on-demand manufacturing services. From prototyping to volume production, Quickparts operates the most advanced technology and possesses the expertise to handle most manufacturing projects.

With facilities stationed around the world, including two Injection Molding centers of excellence, each staffed with experienced engineers laser-focused on meeting your specific requirements as effectively and quickly as possible, you can trust Quickparts as one of the premier suppliers with all of your manufacturing needs.

We have a streamlined approach to mold making, plastic Injection moulding, and engineering processes. We have a separate team of quality control specialists who understand the importance of value, quality, and consistency in moulded products. This is how we differentiate ourselves from our competitors.