Injection Molding Cost Analysis: Simple and Complex Parts.

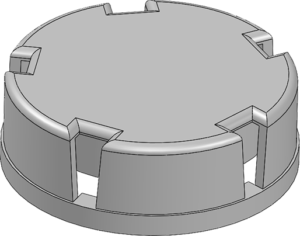

Simple Part

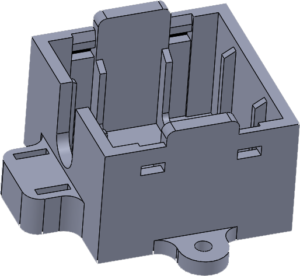

Complex Part

Injection molding cost analysis is a crucial process when considering a manufacturing method, especially for projects with budget constraints. We have conducted a cost analysis to provide you with valuable insights.

We have examined two part designs: one relatively simple and the other more complex. By obtaining quotes from various rapid manufacturing companies and averaging them, we compared the costs to our own injection molding process. This comparison will give you a clear understanding of how pricing per piece affects overall costs across common manufacturing methods.

The following table presents the cost analysis for the simple and complex parts:

Simple Part

| Units | FDM | SLA | SLS | IM |

|---|---|---|---|---|

| 1 | $40.18 | $67.62 | $14.51 | NA |

| 10 | $40.18 | $50.34 | $10.59 | NA |

| 25 | $40.18 | $49.19 | $10.40 | NA |

| 50 | $40.18 | $48.80 | $10.34 | $38.06 |

Complex Part

| Units | FDM | SLA | SLS | IM |

|---|---|---|---|---|

| 1 | $89.19 | $95.88 | $33.99 | NA |

| 25 | $89.19 | $77.09 | $24.36 | NA |

| 50 | $89.19 | $76.70 | $24.22 | $235.16 |

| 100 | $89.19 | $76.70 | $24.08 | $128.80 |

Contrary to other manufacturing methods, injection molding offers greater flexibility and fewer limitations, making it the preferred choice for thermoplastic part production. Although selective laser sintering (SLS) may be less expensive, it is primarily suitable for prototyping due to limited material selection. Injection molding, surprisingly, proves to be more cost-effective than expected.

The advantages of injection molding include the ability to choose from a wide range of engineered grade thermoplastics, select various surface finishes, and manufacture highly complex designs. For simpler designs, injection molding becomes an even more favorable option, particularly when producing fewer than 50 pieces.

For more information go to https://quickparts.com/