Material Selection for Injection Molding

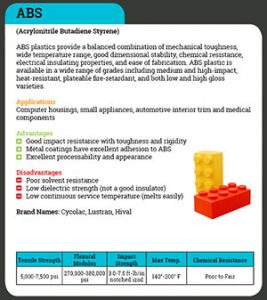

When it comes to injection molding, the choice of material plays a crucial role, especially as you approach the production stage. It’s important to note that the same material used in different manufacturing processes can yield varying results. For example, a part made from ABS through 3D printing will exhibit distinct strength and finish properties compared to a part created via CNC machining. This disparity arises from the fundamental differences between additive manufacturing (layer-by-layer construction) and subtractive manufacturing (cutting away material from a solid block).

While additive manufacturing, such as 3D printing, is often favored for prototyping purposes where specific material qualities are of lesser concern, we have prepared a comprehensive material guide specifically tailored for injection molding.

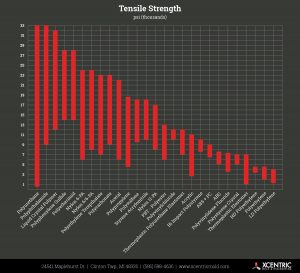

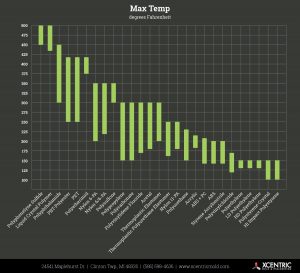

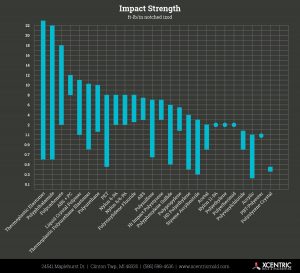

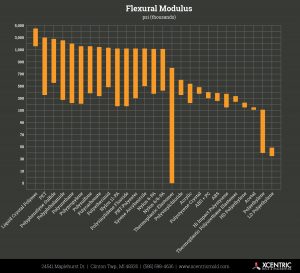

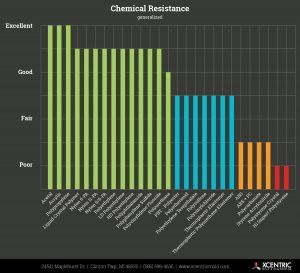

Our guide covers the most commonly used materials, providing a general overview of key factors like tensile strength, impact strength, and chemical resistance. To assist you further, we have included downloadable charts that rank the materials from best to worst for each characteristic.

We believe that this resource will serve as a valuable reference in helping you select the most suitable material for your project.