A furniture designer or manufacturer with years of experience in the field will undoubtedly have a strong understanding of the structural and ergonomic requirements for furniture components. However, they may not have the design skills to create complex geometric shapes or the technical expertise to print them using traditional manufacturing methods.

Quickparts is trusted by some of the world’s largest office furniture companies

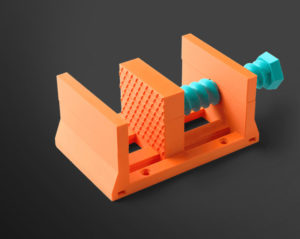

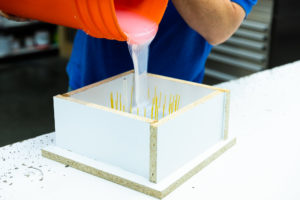

Additive manufacturing has become a valuable tool for professional furniture designers, who are able to create original pieces of furniture without any traditional fasteners or adhesives. By creating unique sets of custom joints for a project, furniture designers can create contemporary pieces of furniture that are both sturdy and stylish.

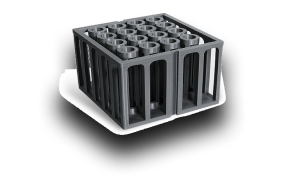

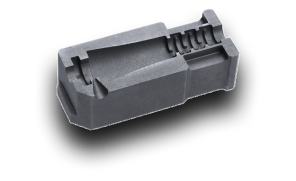

When outsourcing your rapid prototyping needs, it is important to partner with a company that delivers laser-focused precision at industry-leading speeds. Quickparts can print a wide variety of materials, including plastics, metals, and composites allowing you to design and manufacture virtually any component you can imagine. In addition, our 3D printing service and injection mold tooling and parts can offer extensive post-processing services, such as finishing, painting, and assembly. This can take much of the burden off the designer or manufacturer and ensure that the final product is high quality and meets all performance requirements.

Additive and traditional manufacturing have a wide range of uses for furniture and office equipment

Who is QuickParts?

A pioneer in the 3D printing and digital online quoting and ordering world.

We are the originator of a full digital manufacturing platform that delivers on-demand additive and traditional manufacturing services.

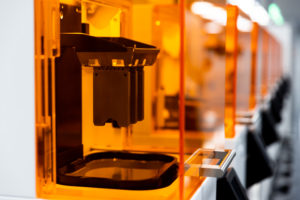

We proudly operate the latest 3D printing and additive manufacturing technology in all 6 of our facilities, strategically located around the world. Each facility is staffed with experienced engineers and manufacturing professionals, all focused on a single goal – meeting our customers’ specific requirements in the time frame they need without sacrificing the quality they deserve.

We understand that being the best requires working with the best. Our in-house expertise spans multiple decades for many of our employees and includes the latest technologies. We also rigorously vet our partner network to help ensure we continue to provide superior service and parts, even those produced outside our own facilities. Combining our in-house capabilities with our partner network allows us to help customers scale quickly, efficiently, and cost-effectively, as needed.

We strive to earn your confidence in every project we touch, so we can accurately say: You can trust Quickparts with all your manufacturing needs, no matter how simple or complex.

Get Started

You’re seconds away from starting your Quickparts project.