SLA 3D Printing with Quickparts

The Ultimate Quick SLA Materials Guide

An overview of the mechanical and physical properties of SLA 3D printing resins run by Quickparts on their large bed and standard stereolithography printers.

Quickparts currently runs the Accura range of 3D printing resins on its SLA printers. Download the TDS, order a sample or request a quote.

SLA Materials

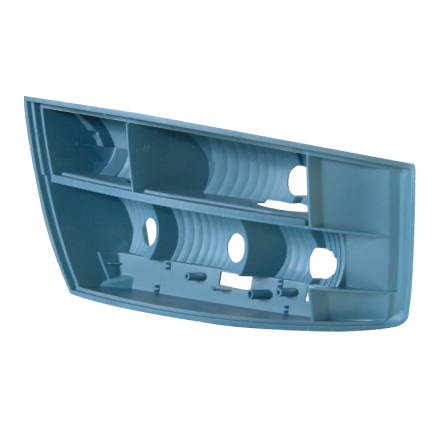

ThermaKor™

Ultra-tough, durable, accurate, smooth white plastic with ABS-like aesthetics

Ultimate Tensile Strength (MPa | PSI)

66-68 | 6900-9800

Heat Deflection Temperature (˚C | ˚F)

65-66 | 149-151 (at 66 PSI) 267-274 | 513-543 (at 66 PSI UV+thermal postcure)

Elongation at Break

1.4-2.4%

Impact Strength (Notched) (J/m | ft-lb/in)

13-17 | 0.24-0.32

Tensile Modulus (MPa | KSI)

7600-11700 | 1100-1700

Accura® CastPro™

Transparent, polycarbonate-like, highly accurate. Specifically for investment casting patterns.

Ultimate Tensile Strength (MPa | PSI)

52–53 | 7540-7690

Heat Deflection Temperature (˚C | ˚F)

51 | 124 (at 66 PSI)

Elongation at Break

4.1 – 8.3%

Impact Strength (Notched) (J/m | ft-lb/in)

43-49.5 | 0.80-0.92

Tensile Modulus (MPa | KSI)

2490-2620 | 361000-380000

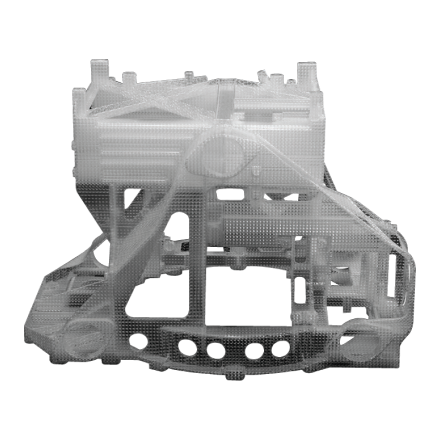

Accura® Extreme™

Ultra-tough, durable, accurate grey plastic with ABS-like aesthetics

Ultimate Tensile Strength (MPa | PSI)

38-44 | 5510-6380

Heat Deflection Temperature (˚C | ˚F)

62 | 144 (at 66 PSI)

Elongation at Break

14 – 22%

Impact Strength (Notched) (J/m | ft-lb/in)

35-52 | 0.70-1.0

Tensile Modulus (MPa | KSI)

1890-2440 | 260-287

Accura® ABS Black

Ultra-tough, durable, accurate grey plastic with ABS-like aesthetics

Ultimate Tensile Strength (MPa | PSI)

45-47 | 6525-6815

Heat Deflection Temperature (˚C | ˚F)

51 | 124 (at 66 PSI)

Elongation at Break

6-13%

Impact Strength (Notched) (J/m | ft-lb/in)

39-56 | 0.73-1.05

Tensile Modulus (MPa | KSI)

1890-2440 | 274-354

Accura® Extreme™ | White 200

Ultra-tough, durable, accurate, smooth white plastic with ABS-like aesthetics

Ultimate Tensile Strength (MPa | PSI)

45-50 | 6530-7250

Heat Deflection Temperature (˚C | ˚F)

47 | 117 (at 66 PSI)

Elongation at Break

7 – 20%

Impact Strength (Notched) (J/m | ft-lb/in)

55-56 | 0.70-1.0

Tensile Modulus (MPa | KSI)

2300-2630 | 334-381

Accura® 48 HTR

Highly heat resistant, transparent and tough

Ultimate Tensile Strength (MPa | PSI)

64-67 | 9280-9720

Ultimate Tensile Strength (MPa | PSI)

65 | 149 (at 66 PSI) 130 | 266 (at 66 PSI UV+thermal postcure)

Elongation at Break

4-7%

Impact Strength (Notched) (J/m | ft-lb/in)

22-29 | 0.4-0.5

Tensile Modulus (MPa | KSI)

2800-3980 | 406-577

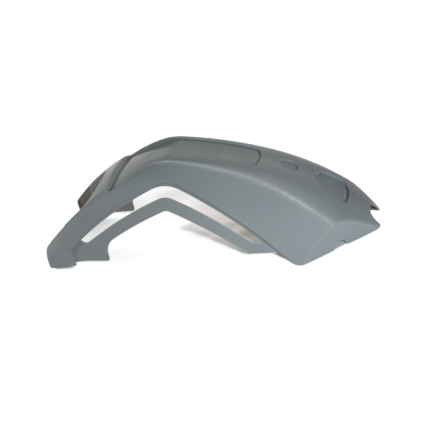

Accura® 25

Polypropylene simulant with excellent flexibility, durability and accuracy

Ultimate Tensile Strength (MPa | PSI)

38 | 5540-5570

Heat Deflection Temperature (˚C | ˚F)

58-63 | 136-145 (at 66 PSI)

Elongation at Break

13-20%

Impact Strength (Notched) (J/m | ft-lb/in)

19-24 | 0.4

Tensile Modulus (MPa | KSI)

1590-1660 | 230-240

Accura® 55

Rigid, durable, smooth white plastic with ABS-like aesthetics

Ultimate Tensile Strength (MPa | PSI)

63-68 | 9200-9850

Heat Deflection Temperature (˚C | ˚F)

51-58 | 131-136 (at 66 PSI)

Elongation at Break

5-8%

Impact Strength (Notched) (J/m | ft-lb/in)

12-22 | 0.2-0.4

Tensile Modulus (MPa | KSI)

3200-3380 | 460-490

Accura® 60

Rigid, strong, clear plastic.

Ultimate Tensile Strength (MPa | PSI)

58-68 | 8410-9860

Heat Deflection Temperature (˚C | ˚F)

53-55 | 127-131 (at 66 PSI)

Elongation at Break

5-13%

Impact Strength (Notched) (J/m | ft-lb/in)

15-25 | 0.3-0.5

Tensile Modulus (MPa | KSI)

2690-3100 | 390-450

Accura® ClearVue

Exceptionally clear, water resistant and durable

Ultimate Tensile Strength (MPa | PSI)

46-53 | 6700-7700

Heat Deflection Temperature (˚C | ˚F)

51 | 124 (at 66 PSI)

Elongation at Break

3-15%

Impact Strength (Notched) (J/m | ft-lb/in)

40-58 | 0.7-1.1

Tensile Modulus (MPa | KSI)

2270-2640 | 329-383