SLA Printing

Your SLA printing needs require advanced technology delivered at rapid speeds.

But even state-of-the-art equipment will fail without a skilled operator, communicative project manager, and customer-centric logistics.

Quickparts has the experience, expert engineers and well-equipped facilities to support SLA printing services that deliver everything from intricate prototypes to large-volume production. Our large-format printers have a build envelope of 1500mm x 750mm x 550mm (59” x 29.5” x 21.5”) for normal resolution prints.

How it Works

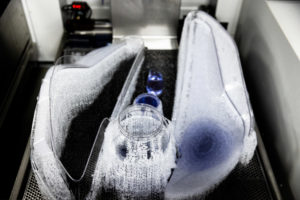

Utilizing a vat of liquid photopolymer resin cured by an Ultraviolet laser to solidify the pattern layer by layer, SLA printing produces high-quality prototypes and parts.

Using SLA printing, Quickparts can address a wide variety of rapid manufacturing applications with many different materials and finishes. Our large bed printers offer the advantage of producing larger and more intricate 3D prints than other 3D printing processes, making it our most versatile 3D printing option.

Let us be your resource to determine which manufacturing process is right for your project.

About Quickparts

Quickparts is a pioneer in the 3D printing world.

We are the originator of a full digital manufacturing platform that delivers on-demand additive and traditional manufacturing services. From rapid prototyping to appearance models and volume production, Quickparts operates the most advanced technology and possesses the expertise to handle any additive manufacturing project.

With facilities stationed around the world, each staffed with experienced engineers laser-focused on meeting your specific requirements as effectively and quickly as possible, you can trust Quickparts with all of your manufacturing needs.

Get Started

You’re seconds away from starting your Quickparts project.

Stereolithography Services – Get The Best Result At An Affordable Price

Do you need to create accurate and high-resolution parts with 3D technology? We have the best professionals to create these parts with stereolithography. Our team is efficient at dealing with this powerful technology for rapid prototyping and low-volume production. So, rely on us for SLA (stereolithography) printing services.

SLA is a 3D printing process, which involves using ultraviolet laser beams to cure photopolymer cross-sections precisely. Based on the CAD data, we build parts and prototypes. Moreover, we have invested in the best tools and casting patterns to provide quality services.

Why choose stereolithography?

- Unrivaled accuracy-Our SLA 3D printers can deliver detailed parts that match your design to perfection

- Production quality-We have highly advanced SLA printers that produce quality parts. So, you do not need to compromise on features, detail and speed!

- A wide selection of SLA materials-You can find different materials for SLA additive manufacturing purposes based on your application needs. Talk to our professionals to discuss the materials that are the best fit for your project.

We are careful with our choice of materials

Our professionals invest in premium quality SLA resins that help in developing accurate prototypes. We always verify the design before making the final production. High-quality surface finish and accuracy have made resin a perfect choice for engineering verification, designer models, and patterns for rubber molds.

There are different SLA materials with various mechanical properties and a review of what materials make sense for your final output is crucial to your initial quote.

Our SLA materials are-

- Rigid- Properties and aesthetics are similar to injection-molded ABS.

- Durable- The materials will provide you with lasting value.

- Clear- For polycarbonate-like components, we choose high-clarity materials.

- Castable- Resins are formulated especially for casting projects.

SLA printing- Our systematic process

We maintain a consistent workflow to provide you with SLA-printed outputs.

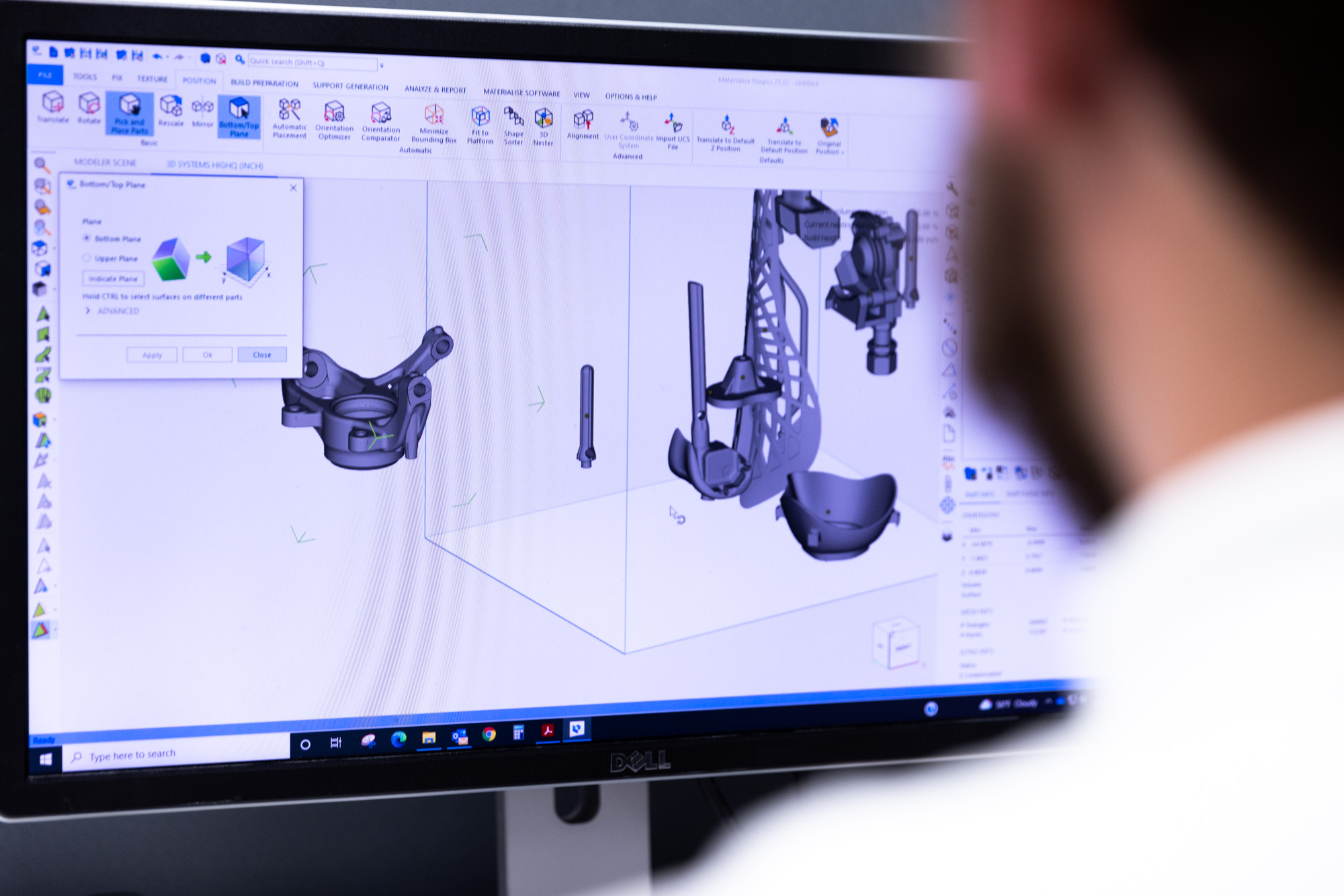

- Design- Using reliable CAD software, we create your product model and transfer it in a 3D format.

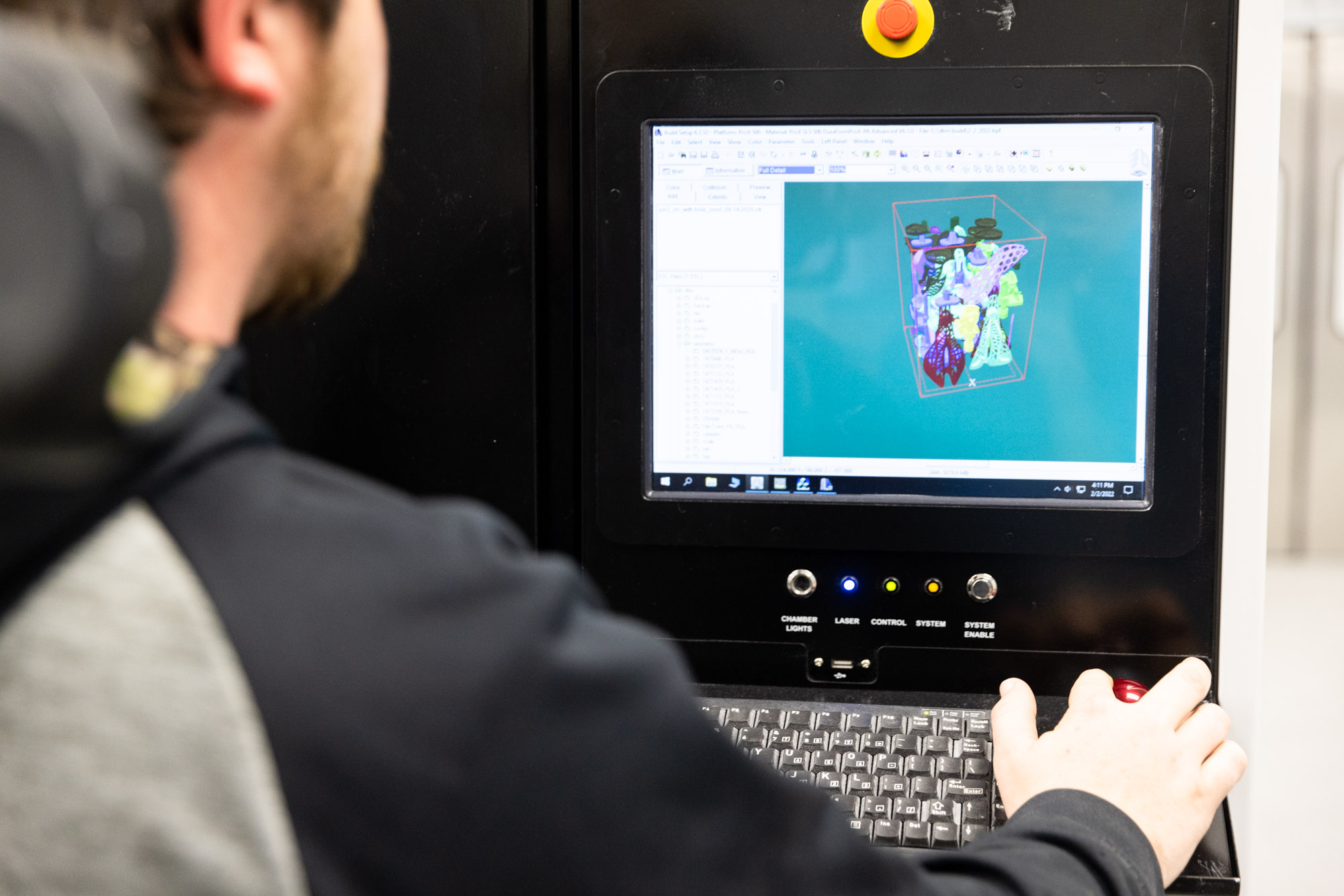

- Print- After creating the proper setup, we start the 3D printing process.

- Post-process- At the end of the printing process, we rinse the parts in isopropyl alcohol to remove uncured resin from the surface.

Do you need to invest in stereolithography services? Start a quote with us today!