SLs Printing

SLS printing is perfect for rapid prototyping, and low- to mid-volume production parts.

Need durable, functional parts with complex geometries? Quickparts’ Selective Laser Sintering (SLS) 3D printing service delivers high-quality prototypes and production parts, quickly and efficiently.

Rapid Prototyping and Production in a Single Day

Experience the speed of creating accurate prototypes and functional production parts in as little as 24 hours. Choose from a variety of nylon-based materials and thermoplastic polyurethane (TPU) to achieve the specific properties your parts require, such as heat resistance, chemical resistance, flexibility, or dimensional stability.

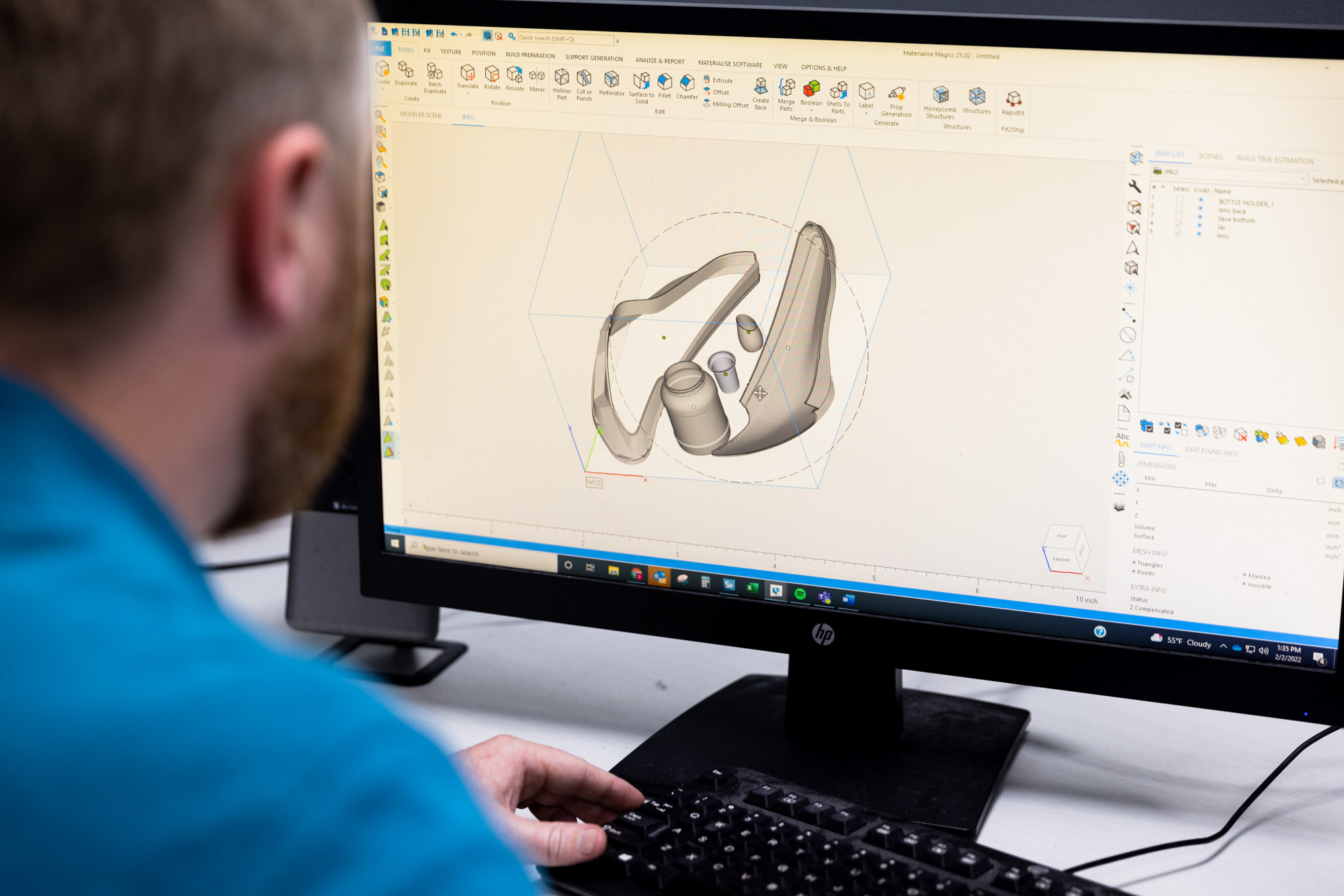

How SLS Printing Works

SLS 3D printing begins with an even layer of powdered material, often thermoplastic polymers or ceramics. A high-powered laser then selectively fuses specific areas of the powder according to your CAD design. The platform lowers, a new layer of powder is spread, and the laser sintering process repeats, building the object layer by layer. Once complete, the object cools and is removed from the powder bed, with excess powder reclaimed for future use. Finally, post-processing techniques may be employed to achieve desired surface finishes or properties.

SLS produces robust, complex geometries, making it suitable for a wide range of applications in industries such as automotive, aerospace, and healthcare. The unsintered powder serves as support for overhanging structures, eliminating the need for dedicated support structures.

Still not sure about SLS? Let us be your resource to determine which manufacturing process is right for your project.

About Quickparts

Quickparts is a pioneer in the 3D printing world.

We are the originator of a full digital manufacturing platform that delivers on-demand additive and traditional manufacturing services. From rapid prototyping to appearance models and volume production, Quickparts operates the most advanced technology and possesses the expertise to handle any additive manufacturing project.

With facilities stationed around the world, each staffed with experienced engineers laser-focused on meeting your specific requirements as effectively and quickly as possible, you can trust Quickparts with all of your manufacturing needs.