In the United States, manufacturers are shifting away from slow, one-off machine shops and toward specialized CNC prototyping companies that can deliver fast, reliable results. Instead of waiting weeks for a first article that may still need major changes, teams now expect to upload a model, get feedback, and see a usable prototype in days, not months.

Modern CNC prototyping services make that possible. Engineers send detailed CAD files, receive rapid pricing with design-for-manufacturability input, and choose from a wide range of metals and plastics. Many providers also bundle finishing, inspection, and small-batch production, so you can validate performance, appearance, and tolerance stack-ups using parts that closely match final production intent.

This review walks through what CNC prototyping is, how the process works in practice, and where it offers the biggest advantages. You’ll also find a breakdown of some of the best CNC prototyping companies and services in the US.

Key Takeaways

- CNC prototyping lets teams test production-grade parts early, using real materials and tight tolerances instead of rough mock-ups or purely digital simulations.

- The strongest CNC partners support the full path from single prototypes to bridge runs and ongoing production, using consistent processes and documented quality controls.

- Centralizing CNC prototyping, small batches, and later production with one provider simplifies sourcing, keeps geometry and process knowledge in one place, and makes design iteration easier to manage across a program.

What Is CNC Prototyping?

CNC prototyping is the practice of using computer-controlled machining to create one-off or short-run parts that behave like final production components. Instead of rough mock-ups, you get precise, fully machined prototypes in production-grade metals and plastics, built directly from your CAD models.

Because CNC stands for Computer Numerical Control, every movement of the tool, spindle speed, and cut path is driven by code instead of handwheels. That digital control lets engineers test fit, function, tolerances, and surface finish under realistic conditions, so they can validate a design confidently before committing to full-scale manufacturing.

How Does CNC Prototyping Work?

CNC prototyping starts with a digital design and turns it into a physical part using computer-controlled machining. Instead of manually guiding tools, the machine follows precise instructions generated from your CAD model. This produces highly accurate prototypes in metals or plastics that match the geometry, tolerances, and surface finish expected in final production. The workflow blends software, machine automation, and iterative refinement to help engineers validate a design before scaling up.

Design and programming:

- Engineers create a 3D CAD model that defines the shape, features, tolerances, and material of the part.

- CAM software converts the model into toolpaths and generates G-code, which tells the CNC machine how to move, how fast to cut, when to change tools, and when to apply coolant.

- Programmers refine feeds, speeds, cutter selection, and fixturing strategies so the part will machine cleanly and capture all functional features.

- A manufacturability review often takes place here, catching thin walls, deep pockets, unsupported features, or other details that could cause chatter, warping, or tool breakage.

Manufacturing:

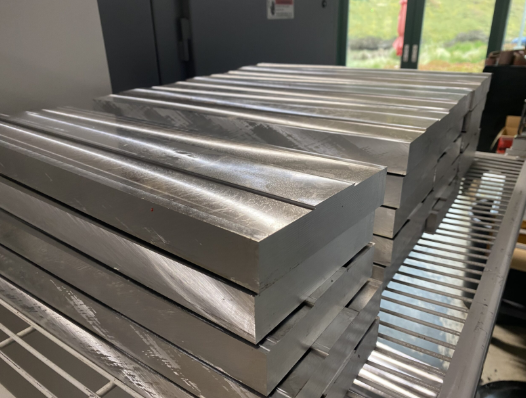

- The CNC machine loads the correct tooling and secures the raw material block or billet.

- The spindle executes the programmed toolpaths, removing material layer by layer through milling, turning, drilling, or a combination of machining operations.

- Sensors and motion controls keep the tool on the exact path, which allows tolerances in the thousandths of an inch.

- Coolant, tool changes, and multi-axis movements are handled automatically, ensuring clean edges, repeatability, and accurate geometries.

- Once complete, the part is deburred and inspected to verify that dimensions, surface finish, and functional features match the design intent.

Iteration:

- Engineers test the machined prototype for fit, performance, strength, and assembly alignment.

- Any issues are adjusted in the CAD model, such as modifying wall thickness, tightening or relaxing tolerances, or redesigning a feature to improve manufacturability.

- Updated toolpaths are regenerated in CAM software, and the CNC machine produces the next revision quickly without new tooling or molds.

- This loop continues until the prototype behaves exactly as required, providing confidence that the design is ready for bridge production or full manufacturing.

Benefits of CNC Prototyping

CNC prototyping gives you a way to test production-grade parts early in development using real materials and tight tolerances.

It delivers accurate feedback on fit, strength, surface quality, and manufacturability so you can refine designs with less guesswork and fewer surprises later in the program. For example, Quickparts helped BionIT, an Italian prosthetics startup, iterate CNC-machined knuckle joints for its Adam’s Hand prosthetic while accommodating last-minute design changes. That kind of agile CNC prototyping shortens the path between first test parts and scalable production and reduces delays and cost surprises. Here’s more benefits of CNC prototyping:

- High precision: Provides tight, repeatable tolerances that closely match final production parts, so you can validate critical dimensions, assemblies, and alignment with confidence.

- Durability: Produces prototypes from solid metal or plastic stock, giving them the strength and structural integrity needed for realistic mechanical, fatigue, and environmental testing.

- Speed: Eliminates the need for molds and complex tooling, allowing teams to go directly from CAD and CAM to machined parts, with design changes handled through quick updates to digital files.

- Versatility: Supports a wide range of metals and plastics, including engineering-grade materials, so you can prototype in the same material planned for production and accurately assess performance and trade-offs.

Best CNC Prototyping Companies & Services

CNC prototyping companies in the US combine advanced machining, experienced engineers, and flexible ordering so you can turn CAD models into functional parts quickly. Some specialize in one-off precision prototypes, while others support the full journey into bridge runs and production.

Here’s a look at some of the best CNC prototyping services to consider.

1. Quickparts

Year founded: 1990

Headquarters: Seattle, Washington, USA

Quickparts provides engineering-led CNC machining services that support projects ranging from single prototypes to high-volume production. The company combines in-house capacity with a global supplier network and uses its QuickQuote® platform to deliver instant pricing and lead-time estimates.

Quickparts focuses on helping teams move quickly from digital models to physical parts without sacrificing quality. Design-for-manufacturability reviews, clear tolerance guidance, and process selection support enable engineers to catch issues early and choose the right materials and finishes for each application.

For CNC prototyping, Quickparts focuses on production-grade materials and real testing conditions. Teams can order one-off or short-run parts in metals and polymers such as aluminum, stainless steel, mild steel, high-nickel alloys, brass, copper, ABS, nylon, POM, polycarbonate, acrylic, PEI, and PEEK, then keep the same machining approach as they move into bridge and higher volume work.

Customers in aerospace, medical, automotive, and industrial markets use Quickparts as a single partner for CNC prototyping, bridge builds, and scaled production when they need reliable lead times and consistent dimensional control. Facilities operate under ISO 9001:2015 with ITAR registration, and CNC operators bring an average of 10 years’ experience to complex metal and plastic parts.

CNC prototyping services:

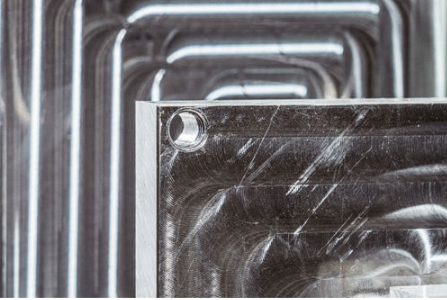

- CNC milling: Produces precision parts with complex geometries and critical surface finishes. The process removes material from a stationary workpiece using rotating tools, enabling accurate prototypes, functional components, and multi-part runs in metals and polymers such as aluminum, stainless steel, brass, copper, acetal, nylon, PEEK, and polycarbonate. Parts are inspected to maintain dimensional accuracy around ±0.001.

- CNC turning: Creates cylindrical and conical components by rotating the workpiece against a stationary cutting tool. This method suits shafts, bushings, tubes, and threaded features, allowing Quickparts to support both one-off prototypes and larger prototype batches. Pre-production design reviews help identify geometry or tolerance risks before machining begins, improving first-article success and repeatability.

Other manufacturing and production services:

- Additive manufacturing: Supports stereolithography (SLA), selective laser sintering (SLS), direct metal printing (DMP), fused deposition modeling (FDM), and other 3D printing processes for visual models, functional prototypes, and end-use parts.

- Sheet metal fabrication: Includes laser cutting, water jetting, stamping, bending, welding, and finishing operations to produce enclosures, brackets, and structural assemblies in materials such as aluminum, stainless steel, brass, and titanium.

- Die casting: Provides hot-chamber (zinc) and cold-chamber (aluminum) die casting for small- to mid-sized metal parts, delivering consistent surface quality and dimensional repeatability for production programs.

- Cast urethane: Produces cast urethane prototypes and master patterns for investment casting and low-volume molded parts, allowing teams to validate designs without committing to full injection tooling.

- Injection molding: Offers rapid and production injection molding from single-cavity tools to multi-cavity, high-volume setups. Capabilities include insert molding, overmolding, stack molds, and hot-runner systems, with typical tooling tolerances down to about ±0.07 mm depending on part size and design.

- Rapid prototyping: Supports fast-turn prototypes across CNC machining, 3D printing, casting, and molding, enabling engineers to compare processes, validate performance, and refine designs before locking in a production route.

Learn more about Quickparts for CNC prototyping

2. ARRK

Year founded: 1948

Location: San Diego, California, USA

ARRK is a global product development provider that supports projects from early design models through low-volume production. Its North American operation offers CNC machining for prototyping alongside other fabrication processes so teams can test production-like parts in metals and plastics.

The company combines 3-axis and 5-axis machining centers with material and process selection support, covering work that ranges from single functional prototypes to small batches. CNC services sit inside a broader product development workflow that includes concept modeling, mockups, and preparation for tooling and molding.

CNC prototyping services:

- CNC machining for prototyping: Machines low-volume parts in metals and plastics to reflect final form, fit, and function.

- 3-axis CNC milling: Cuts prismatic parts from solid stock for brackets, housings, and structural components.

- 5-axis CNC milling: Applies multi-axis motion to reach complex surfaces and features in a single setup.

- Low-volume CNC machining: Uses production-representative setups to support short runs ahead of tooling or molding.

Other manufacturing and production services:

- 3D printing: Produces prototypes and pre-production parts with additive processes across multiple polymers.

- Urethane casting: Casts production-like parts in polyurethane using silicone tooling for limited batches.

- Microwave molding: Molds thermoplastic prototypes with a specialized heating process for molded test parts.

- Injection molding: Supplies molded components for programs that move beyond CNC into tooling-based production.

- Die casting: Manufactures metal components using permanent molds for structural and enclosure applications.

- Design and styling models: Builds presentation-quality design models, mockups, and soft goods samples for review.

3. Astro Machine Works

Year founded: 1984

Location: Ephrata, Pennsylvania

Astro Machine Works provides CNC machining services that use computer control to run milling, turning, and related operations. The company operates a dedicated machining facility in Pennsylvania with multi-axis equipment, CAD/CAM workflows, and quality systems suited to regulated and technical applications.

The team supports CNC prototyping and production parts across sectors such as aerospace, defense, medical, electronics, and energy. Engineers work with customers on part geometry, tolerances, and materials so projects can move from early prototypes to ongoing production with a single machining partner.

CNC prototyping services:

- CNC mills: Use rotating cutting tools on stationary workpieces to create rectangular or prismatic parts with flat faces, pockets, and contours.

- CNC lathes: Rotate workpieces around fixed tools to form cylindrical features, threads, grooves, and bores.

- CNC plasma cutters: Cut conductive metals along programmed paths with a focused plasma arc to produce defined external profiles.

- CNC electric discharge machines (EDM): Erode conductive material with controlled spark discharges to create fine details and sharp internal corners.

- CNC water jet cutters: Cut shapes and holes with high-pressure water and abrasive media without introducing heat-affected zones.

Other manufacturing and production services:

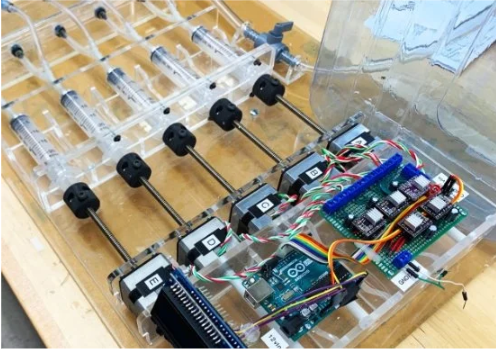

- Custom machine building: Designs and assembles bespoke machinery and automation systems, including fabrication, machining, wiring, and final assembly.

- Machine repair, rebuilding, and refurbishment: Diagnoses existing equipment, then restores, upgrades, or retrofits machines to specified operating conditions.

- Panel wiring and control systems: Builds custom control panels and integrates PLCs, control hardware, and safety systems for industrial equipment.

- Reverse engineering: Recreates or updates unavailable or legacy parts using dimensional inspection and CAD and solid modeling.

4. Empire Group

Year founded: 1999

Location: Attleboro, Massachusetts, USA

Empire Group provides low-volume manufacturing and prototyping services that cover CNC machining, 3D printing, and model making under one roof. The company supports programs that move from high-fidelity prototypes into short-run production, serving sectors such as aerospace, automotive, defense, medical, industrial, and consumer products.

CNC prototyping services:

- CNC milling: Machines metal, plastic, and composite parts with complex geometries and specified tolerances for prototypes, molds, and low-volume components.

- CNC turning: Produces cylindrical parts such as shafts, bushings, and fittings with controlled concentricity and surface finish.

- Rapid CNC prototyping: Uses CNC setups to create prototypes that match final form, fit, and function for design validation and testing.

- Short-run CNC production: Runs small batches of parts in production-grade materials so teams can bridge between prototyping and full-scale manufacturing.

Other manufacturing and production services:

- 3D printing: Produces models and functional parts for displays, enclosures, and product development across multiple additive processes.

- Prototyping and model making: Builds appearance models, trade show displays, and functional mockups for review, marketing, and engineering use.

- Sheet metal fabrication: Cuts, forms, and assembles sheet metal parts for brackets, panels, and structural elements.

- Painting and finishing: Applies coatings, textures, and cosmetic finishes to prototypes and production parts to match visual and branding requirements.

5. Evco Plastics

Year founded: 1964

Location: DeForest, Wisconsin, USA

Evco Plastics is a contract manufacturer that focuses on plastic injection molding and related engineering services for production parts and molded assemblies.

Prototyping sits alongside tooling and molding as a core service. Evco uses CNC machining and additive processes to create prototype parts and prototype molds so customers can evaluate form, fit, and function before committing to larger runs. These prototypes can be finished and decorated to match near-final appearance for engineering reviews, marketing use, or early field testing.

CNC prototyping services:

- CNC machined plastic prototypes: Machines parts in production-like plastics so teams can check geometry, assembly clearances, and functional behavior before tooling changes.

- Prototype injection molds: Builds aluminum or steel prototype molds, including single-cavity and MUD inserts, to mold short runs of parts under production-like conditions.

- Low-volume molded trials: Uses prototype tooling for short runs that validate gating, filling, and part performance ahead of multi-cavity or full-scale tooling.

Other manufacturing and production services:

- Plastic injection molding: Molds parts across a range of press sizes for applications such as large parts, industrial products, medical components, and consumer goods.

- Tooling design and build: Designs and manufactures injection molds, including multi-cavity and specialty tools, supported by internal engineering and moldmaking teams.

- Additive prototyping: Produces parts using SLS, SLA, and FDM processes for concept models, fit checks, and early functional evaluations.

- Contract manufacturing: Provides integrated services that can include molding, secondary operations, and logistics within a single manufacturing partner structure.

6. Fictiv

Year founded: 2013

Location: San Francisco, California

Fictiv operates a digital manufacturing platform that connects engineering teams with a managed global network of CNC and fabrication partners instead of running its own factories. The company coordinates quoting, manufacturability feedback, quality checks, and logistics while suppliers carry out production.

Its workflow centers on uploading CAD files through an online interface, configuring requirements, and receiving automated DFM commentary with pricing. Orders are then routed to vetted partners, and customers track project status within the same platform for both prototype and production work.

CNC prototyping services:

- CNC milling: Uses 3-, 4-, and 5-axis machines to produce prismatic and freeform parts in metals and plastics.

- CNC turning: Machines pins, shafts, spacers, and other cylindrical parts, with live tooling available for milled features on turned components.

- Electrical discharge machining (EDM): Applies wire and sinker EDM to cut deep pockets, sharp internal corners, and narrow slots in conductive materials.

Other manufacturing and production services:

- 3D printing: Provides FDM, SLS, SLA, PolyJet, and MJF for polymer prototypes and end-use parts.

- Injection molding: Supplies molded components through partner tools for prototyping and production programs.

- Sheet metal fabrication: Cuts, bends, and forms sheet metal for brackets, enclosures, and structural parts.

- Compression molding: Molds durable components in rubber and related materials using matched tooling.

- Urethane casting: Delivers cast urethane parts for low-volume needs without permanent tooling.

- Die casting: Produces metal components using partner foundries for programs that require cast housings or structural parts.

7. Pacific CNC Machine Co.

Year founded: 2001

Location: Carlsbad, California, USA

Pacific CNC Machine Co. operates as a full-production precision machining and assembly shop serving commercial and industrial customers. The company runs horizontal lathes, vertical mills, and a gantry router for large-format parts, supported by Hypermill, Solidworks, and Surfcam for programming and design. Its team handles work that ranges from early prototype design through scaled production runs, with processes structured around documented quality and customer audit requirements.

CNC prototyping services:

- Prototype design and CAD: Prepares manufacturable part models and machining strategies using CAD and CAM tools so teams can translate concepts into machine-ready geometry.

- CNC milling: Uses vertical and 5-axis mills to machine metal and plastic prototypes that require flat faces, pockets, contours, and detailed features.

- CNC turning: Machines round components on precision lathes, including shafts, bushings, and threaded parts, for fit and assembly checks.

Other manufacturing and production services:

- Short- and long-run production: Supports production machining for recurring orders, using the same workflows and equipment as prototype work.

- Assembly: Builds subassemblies that combine machined parts with hardware or fabricated components.

- Light fabrication and finishing: Performs basic fabrication tasks and finishing steps so parts arrive ready for downstream use or integration.

8. Protolabs

Year founded: 1999

Location: Maple Plain, Minnesota, USA

Protolabs runs a digital CNC machining service that links online quoting, manufacturability analysis, and automated production for prototype parts. Engineers upload CAD files, receive geometry checks focused on milling and turning constraints, then select materials, quantities, and finishes for CNC prototype runs without building in-house capacity.

CNC prototyping services:

- CNC milling: Uses three- and five-axis milling to cut metal and plastic blocks into parts with flat faces, pockets, contours, and detailed features for functional prototypes.

- CNC turning: Machines cylindrical parts such as shafts, spacers, and housings using turning centers with optional live tooling for features on side faces.

Other manufacturing and production services:

- Injection molding: Molds plastic parts using production-grade resins and bridge tooling for low to mid-volume orders.

- 3D printing: Provides polymer and metal additive processes such as powder bed fusion and resin-based printing for concept models, fixtures, and end-use parts.

- Sheet metal fabrication: Cuts, bends, and forms sheet metal into brackets, enclosures, and structural components with basic finishing options.

9. TFG USA

Year founded: 1980

Location: Bingham Farms, Michigan, USA

TFG USA (The Federal Group) is a custom metal components manufacturer that uses CNC prototyping to turn digital designs into repeatable, production-ready parts. Their team blends engineering support with automated machining so customers can validate fit, strength, and manufacturability before scaling to full metal fabrication.

CNC prototyping services:

- CNC prototyping for metal components: Uses programmed milling, cutting, and forming paths to produce accurate early prototypes.

- Rapid CNC prototyping: Reduces human error and accelerates early-stage development for testable metal parts.

- Custom metal prototyping: Produces non-standard geometries and tightly controlled dimensions for specialized components.

- CNC-supported metal fabrication prototyping: Automates forming, bending, and cutting steps for complex metal prototype parts.

Other manufacturing and production services:

- Metal fabrication: Provides welding, extrusion, stamping, folding, bending, spinning, finishing, and cutting for metal parts.

- Castings and forgings: Uses metal forming methods to support production-volume components.

- Assembly services: Builds custom metal components into finished or semi-finished products ready for integration.

10. UPTIVE

Year founded: 2016

Location: Libertyville, Illinois, USA

UPTIVE is an advanced manufacturing company that brings CNC machining, rapid prototyping, and additive manufacturing together under one organization. The company was formed through the combination of GoProto, RE3DTECH, Phoenix Proto, and Stanfordville Machine. It serves aerospace, automotive, medical, electronics, and industrial customers that need both prototype parts and ongoing production support, with digital quoting, material selection guidance, and documented quality systems.

CNC prototyping services:

- CNC milling: Uses 3, 4, and 5-axis milling centers to machine jigs, fixtures, and functional components in aluminum, stainless steel, titanium, engineering polymers, and composite materials.

- CNC turning: Applies 2 to 8-axis lathes and Swiss turning to produce shafts, bushings, and small complex parts with slots, grooves, flats, and axial or radial holes for tight tolerance assemblies.

- Rapid CNC prototyping: Produces large and intricate prototypes directly out of CAD data in metals, polymers, and composites, with painted, plated, polished, or clear surface options for appearance and functional evaluation.

Other manufacturing and production services:

- Rapid prototyping: Combines CNC machining, 3D printing, sheet metal work, and rapid tooling so engineering teams can build functional prototypes without committing to long-term tooling at an early stage.

- Additive manufacturing: Provides DMLS, SLS, FDM, SLA, HP Multi Jet Fusion, and PolyJet processes for plastic and metal parts that require internal channels, lattice structures, or other complex geometries.

- Sheet metal fabrication: Cuts, bends, and forms sheet stock into brackets, enclosures, panels, and structural elements in quantities that range from single parts to low-volume batches.

11. Xometry

Year founded: 2013

Location: North Bethesda / Gaithersburg, Maryland, USA

Xometry operates a digital manufacturing marketplace that connects engineering teams with a large network of CNC machine shops and other manufacturing suppliers. Customers upload CAD files through the Instant Quoting Engine, then review pricing, lead times, and basic design-for-manufacturability input before placing CNC machining orders. CNC prototyping and production use a certified quality system that includes ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D, along with ITAR registration for controlled work.

CNC prototyping services:

- CNC milling: Uses 3-, 4-, and 5-axis milling centers to machine metal and plastic blocks into prismatic and contoured parts.

- CNC routing: Machines sheet and plate components using CNC routers for panels, enclosures, fixtures, and other large-format parts in metals and rigid plastics.

- High-volume CNC machining: Extends the same CNC processes to larger batches so teams can move individual prototype geometries into repeat production.

Other manufacturing and production services:

- 3D printing: Provides polymer and metal additive processes such as SLS, MJF, FDM, SLA, and others for concept models, fixtures, and functional components.

- Sheet and tube fabrication: Cuts, bends, and forms sheet and tube stock into brackets, frames, and structural parts with welding and basic finishing where required.

- Injection molding: Supplies molded plastic parts using soft or production tooling so projects can progress beyond CNC prototypes into higher-volume molded production.

Finishing and post-processing: Offers bead blasting, tumbling, anodizing, chem film, passivation, powder coating, plating, and related surface treatments so machined parts reach specified cosmetic and corrosion-resistance requirements.

How to Choose Between CNC Prototyping Companies & Services

Choosing a CNC prototyping partner affects design validation, schedule risk, and how smoothly you move into production. Instead of just comparing price and lead time, evaluate each provider across a few core areas.

Here are the key factors to review:

- Quality and precision: Indicates how well the provider holds tolerances, controls process variation, and inspects parts so prototypes behave like production components.

- Quick turnaround: Shows the provider’s ability to quote, schedule, and ship CNC prototypes in line with your development milestones instead of slowing design decisions

- Flexible quantities and complexity: Reveals how the shop handles single prototypes, short runs, and complex geometries so you can use one partner across multiple project stages

- Pre-production review: Reflects the provider’s willingness to review models, flag machining risks, and suggest design or tolerance adjustments before cutting material

- Experience: Highlights the team’s track record with similar materials, part types, and industries so you can rely on practical machining knowledge, not trial and error

- Customer service: Shows how clearly the provider communicates status, responds to engineering questions, and resolves issues when parts need clarification, rework, or iteration

Work with the Best CNC Prototyping Company in the US

The CNC prototyping partner you choose affects how clearly you understand real-world performance before committing to full production. Quickparts structures its CNC machining services around that goal, so engineering teams can base decisions on production-grade parts instead of rough stand-ins.

With Quickparts, you can start with a handful of prototypes and stay with the same provider as quantities increase, part families expand, or designs change. There are no fixed limits on part count or complexity, which lets you use one CNC workflow for early trials, test batches, and follow-on runs.

Every new project includes a design for manufacturing review. This helps identify potential machining issues early and align expectations on features, surfaces, and overall feasibility before material is cut. For companies managing tight schedules or regulated applications, this review reduces the risk of prototypes that look right on paper but do not match operational needs.

Quickparts also brings long-standing CNC experience and an established global network, so capacity and operator expertise are in place when you need additional revisions or new variants. That combination gives companies a straightforward way to validate designs, compare options, and move toward production using a consistent CNC approach.

Ready to see how your next design behaves as a machined part?

Get your free quote with Quickparts today.

CNC Prototyping FAQs

Which manufacturing process is the best choice for prototyping?

The best process depends on what you need to evaluate. CNC machining suits functional prototypes that require tight tolerances and production-grade materials. 3D printing works for quick form checks or complex internal features. Many teams use both during early development.

How does a CNC work step by step?

A CAD model is converted into toolpaths, the machine loads material, and programmed movements remove material until the final geometry is reached. Cutting, tool changes, and coolant are controlled automatically. The finished part is then inspected against design requirements.

What is the hardest material for CNC machining?

Heat-resistant alloys and certain hardened steels tend to be the most challenging because they create high tool loads and require controlled cutting conditions. These materials can still be machined, but they demand careful programming, appropriate tooling, and defined tolerance expectations.