Choosing an injection molding partner in the United States can directly impact your production cost, lead time, and part quality. Whether you’re scaling up or building a prototype, it’s essential to work with companies that deliver consistently and communicate clearly.

This list focuses on companies with proven track records in injection molding. We evaluated them based on production capabilities, turnaround times, and industry specialization.

In this article, you’ll find practical comparisons of the best injection molding companies, including their core services, tooling options, and what types of projects they’re best suited for.

How to Evaluate Injection Molding Suppliers

Choosing the right injection molding supplier can directly affect your product timeline, cost structure, and part reliability. Speed and part quality should be standard—but what matters more is the supplier’s ability to function as a long-term manufacturing partner.

When evaluating injection molding vendors, look for companies who:

- Customer-driven collaboration: Ask targeted questions and tailor solutions based on your application, timeline, and constraints.

- Speed and precision: Deliver clear timelines, rapid tooling, and high-accuracy parts within short lead times.

- Iteration: Support mid-process design changes and scale production without starting from scratch.

- Transparent communication: Provide regular updates and flag risks early through a dedicated project contact.

- Customization capabilities: Adapt tooling and processes to match complex geometries and special part features.

- Design consultation: Review CAD files to identify draft issues, tolerance problems, and geometry concerns before tooling.

- Tooling capabilities and lead times: Offer aluminium and steel tools with lead times that align with your schedule and budget.

- Scalability from prototype to production: Manage small batches and ramp up to high volumes without retooling.

- Material flexibility and knowledge: Stock a wide range of thermoplastics and guide selection based on application needs.

- Achievable tolerances and repeatability: Explain what tolerances are realistic for your design and ensure consistency at scale.

- Manufacturing footprint and in-house capabilities: Produce tools and parts in-house to reduce lead times and improve quality control.

- Communication and project management: Assign a single contact to manage the entire project and keep you informed.

- Advanced technical capabilities: Handle complex features like inserts, overmolds, and multi-cavity tools with proven expertise.

- Inspection and quality control standards: Check parts throughout production and document measurements to ensure consistency.

- Long-term fit: Reduce costs and errors by supporting your product lifecycle from early design through full production.

Best Custom Injection Molding Companies & Services in the US

This list shows the top-performing US-based injection molding companies based on service range, turnaround speed, and tooling flexibility. Let’s take a look:

1. Quickparts

Year founded: 1990

Headquarters: Seattle, Washington, USA

Quickparts specializes in injection molding for prototyping, bridge tooling, and high-volume production. Their in-house tooling, global partner network, and fast turnaround times make them a reliable choice for companies that need parts quickly and at scale. They offer Class 105 to Class 103 molds, supporting everything from early design validation to millions of production cycles.

They support 15+ stock materials and allow customers to supply their own. Quickparts includes a design-for-manufacturing (DFM) review with every project. This helps identify issues before tooling starts, saving time and cost later. Quickparts is ISO 9001:2015, ISO 27001:2022, and ITAR registered.

They support tight tolerances, with tooling precision down to ±0.07 mm. Their engineers work closely with customers to meet functional and cosmetic part requirements. Their process is built for speed and predictability. Prototype parts can ship in as little as one week, and full production runs in 4 to 8 weeks.

In practical terms, Quickparts is best suited for companies that:

- Need fast quotes and reliable timelines

- Want full control over tooling and materials

- Are looking for a supplier that supports both prototyping and production

- Prefer local production with clear communication and engineering support

Injection molding solutions:

- Quick molded parts: Tools machined in aluminum to produce prototype or low-volume parts. The tooling life is approximately 250 parts, with maximum part size capped at 80 × 80 × 50 mm. Design limitations apply (e.g. no sliders/lifters), and over 15 stock materials are supported.

- Prototyping: Steel or aluminum molds used for medium volumes, up to 2,500 parts. Maximum part size is 500 × 500 × 100 mm. These larger tools ship in 2–6 weeks after approval and offer guaranteed accuracy within standard tolerances.

- Production molding: Hardened steel molds built to support runs from 10,000 to millions of parts. Accepts customer-supplied materials and supports automated press loading. Maximum tooling size up to 1500 × 1000 × 350 mm and delivery in 4–8 weeks.

- Advanced process techniques: Includes overmolding, insert molding, stack molds, multi-cavity tooling, and hot-runner systems. Designed to support complex part geometries and multi-material designs.

Other manufacturing and production services:

- CNC machining: Delivers 3-, 4-, and 5-axis CNC milling and turning with tolerances as tight as ±0.001, suitable for both metal and plastic parts in low- to high-volume runs.

- Additive manufacturing: Support stereolithography (SLA), selective laser sintering (SLS), direct metal printing (DMP), fused deposition modeling (FDM), and other digital fabrication methods for prototyping and end-use parts.

- Sheet metal fabrication: Includes laser cutting, water jetting, stamping, bending, welding, and finishing processes to produce enclosures and assemblies across materials like aluminum, stainless steel, brass, and titanium.

- Die casting: Provides traditional die casting using both hot‑chamber (zinc) and cold‑chamber (aluminum) methods for small‑ to mid‑sized metal parts with consistent surface quality and dimensional repeatability.

- Cast urethane: Produces cast urethane prototypes and master patterns for investment casting applications, offering support from pattern through low‑volume casting. This is a great solution for low-volume manufacturing of molded parts.

- Rapid prototyping: Supports fast-turn prototypes across multiple manufacturing processes to help validate designs and iterate quickly.

2. Abtec, Inc.

Year founded: 1981

Location: Bristol, Pennsylvania, USA

Abtec, Inc. provides custom plastic injection molding for prototyping, short-run, and full production. The company also supports mold and part design based on customer requirements.

Abtec operates molding machines ranging from 28 to 240 tons of clamping pressure and can mold up to 16 ounces of material per cycle. They work with both commodity and engineering-grade thermoplastics. Designs can be submitted in SolidWorks, AutoCAD, and other CAD file types. The company reviews parts for manufacturability to help reduce issues before production.

Abtec offers molding for parts used in diagnostic testing and related equipment. These parts are produced under conditions that support reduced hydrocarbon contamination for OEMs that require it.

Injection molding solutions:

- Custom tooling and production molding using engineering-grade resins.

- Tooling types include single-cavity, multi-cavity, hot-runner, cold runner, and two-shot molds.

- Insert molding, overmolding, and automated assembly-capable tooling solutions.

Other manufacturing and production services:

- CNC machining and value-added services: milling, drilling, tapping, heat staking/insertion, hot stamping, ultrasonic welding/inserting, trimming, and sorting.

- Mold repair, refurbishment, management, and lifecycle maintenance.

3. All-Plastics LLC

Year founded: 1964

Location: Holdsworth Dr, Kerrville, TX

All-Plastics LLC produces injection molded parts and provides assembly services for medical, pharmaceutical, packaging, industrial, and consumer applications. The company uses scientific molding to support requirements for accuracy, traceability, and process control.

They design and build molds, create prototypes, and run production molding. They report an accuracy range of +/- 25 microns.

The company follows documented quality procedures and operates under ISO 13485 certification. They track production metrics related to efficiency and sustainability. All-Plastics also performs secondary operations after molding. These include assembly and other finishing steps.

Injection molding solutions:

- Offers multi-shot, insert molding, overmolding, cavity sorting, and in-mold labeling as part of advanced tooling capabilities.

- Maintains process control via real-time data capture, including temperature/pressure sensors and Automated QC systems.

Other manufacturing and production services:

- Supports mold building, prototyping, and engineering plastic services integrated with mold design review and preventive tool maintenance.

- Provides assembly, decorative printing, in-mold labeling, packaging, and custom kitting for various production scales.

- Conducts a full quality testing suite, including moisture analysis, dimensional measurement, and real-time statistical process tracking.

4. American Tool & Mold

Year founded: 1978

Location: Clearwater, Florida, USA

American Tool & Mold designs and builds multi-cavity, thin-wall, stack, hot runner, unscrewing, and two-shot injection molds. The company supports both one-off and multi-tool programs. ATM uses a molder-focused approach that includes design for manufacturing and failure mode effect analysis (FMEA) to assess part geometry, ejection, cycle time, and mold flow.

Their mold manufacturing capabilities include hardened steel machining, EDM, grinding, and high-speed milling with multi-axis equipment. Mold management includes maintenance, rebuilding, and retrofitting services based on mold condition, part geometry, and material use.

Injection molding solutions:

- Maintains in‑house molding presses, including 20 high‑efficiency machines, vertical rotary insert, and two‑color molding for validation, pilot runs, or production.

Other manufacturing and production services:

- Offers mold maintenance programs including preventive upkeep, refurbishment, retrofit, and lifecycle tracking to optimize uptime and tool performance.

5. Berry Global

Year founded: 1967

Location: Evansville, Indiana

Berry Global supplies injection molded components such as caps, closures, containers, and technical parts for industries including consumer goods, healthcare, and packaging. The company supports various molding processes, including compression, cube, insert, and multi-component molding across its global network.

Tooling capabilities include in-house design, manufacturing, and lifecycle maintenance of injection, blow, compression, and thermoforming molds. This tooling infrastructure was consolidated into a unified global platform known as Berry Global Tooling Services, supporting regional production sites.

The company operates over 10 global tooling facilities and performs mold management activities, including maintenance, refurbishment, and design validation. Recent acquisitions such as F&S Tool have expanded its portfolio with high-output compression and hot-runner molding capabilities in the closures and bottle segment.

Injection molding solutions:

- Caps, closures, tubs, bottles, and containers for healthcare, food, personal care, home care, and industrial markets.

- Compression molding, cube molding, insert molding, multi-component injection molding.

Other manufacturing and production services:

- In-house tooling services, including design, build, testing, and reverse engineering support.

- On-site production support, performance validation, and process troubleshooting during product launches and conversions.

- Decorating and labeling services, including in-mold labels, hot stamping, photo‑realistic, and foil printing.

- Media support services such as warehousing, distribution, compliance reporting, and more integrated logistical support.

6. Extreme Molding

Year founded: 2002

Location: Menands, New York, USA,

Extreme Molding operates a facility specializing in custom silicone and plastic injection molding, primarily serving healthcare, consumer, and life science markets. The company processes injection molding, overmolding, compression, and transfer molding for products like medical-grade housings, silicone baby items, and ergonomic grips.

The organization offers full-service manufacturing including mold sourcing, design support, CAD assistance, and secondary operations such as packaging, color matching, and assembly. It maintains manufacturing traceability, adheres to FDA and QRS standards, and meets ISO 9001:2015 and ISO 13485:2016 certification requirements

- Offers silicone injection molding.

- Supports limited and high-volume manufacturing with a full-service model that includes mold sourcing, validation, and project launch support.

Other manufacturing and production services:

- Includes packaging, assembly, color matching, fulfillment, and value-added secondary operations such as die-cutting, adhesives, post-curing, and hole punching.

- Offers CAD drawing support, packaging design, order fulfillment via platforms like Amazon and Shopify, and just-in-time shipping worldwide.

7. GSH Industries

Year founded: 1986

Location: Strongsville, Ohio, United States

GSH Industries provides custom plastic, rubber, and aluminum extrusions and injection molding services from CAD drawings through delivery.

The company applies engineering support to match materials and production methods to customer specifications across markets such as automotive, construction, medical, and consumer goods.

GSH makes injection molded parts ranging from small precision components to large assemblies using a range of press tonnages. The molding equipment portfolio supports part complexity and varied volume demands. The organization also integrates extrusions, fabrication, and mold tool making as part of its tooling and secondary operation services.

Injection molding solutions:

- Offers insert molding, ultrasonic welding, heat staking, mold temperature controllers, and material dryers as part of standard molding equipment.

- Works with a wide range of thermoplastic resins, including polyethylene, polypropylene, polycarbonate, nylon, glass-filled nylon, acrylic, and specialty engineered plastics.

Other manufacturing and production services:

- Provides plastic, aluminum, and rubber extrusion services.

- Maintains engineering support from design through prototyping and tooling, including CAD review, material selection guidance, and process consultation.

- Includes secondary fabrication services such as CNC milling, wire EDM, metalworking, cutting (water jet, plasma), grinding, welding, and finishing with tight tolerances.

8. Ironwood Plastics

Year founded: 1979

Location: Ironwood, Michigan

Ironwood Plastics specializes in close-tolerance injection molding, including capabilities in insert molding, overmolding, and continuous (reel-to-reel) molding.

The company supports product lines in industries such as automotive, medical, electronics, and defense.

It operates two facilities, one in Ironwood, MI, and the other in Two Rivers, WI, and manages engineering, tooling, molding, and secondary operations internally. Ironwood joined CTB, Inc. (part of Berkshire Hathaway) in 2010 and holds ISO 9001 and IATF 16949 certification.

Injection molding solutions:

- Offers tight‑tolerance injection molding in materials using processes such as insert, overmolding, and continuous reel-to-reel molding.

- Supports two-shot and transfer molding capabilities, including recent additions like rotary platen two-shot molding.

- Serves applications requiring precision, such as connectors, housings, medical components, and battery-related automotive parts.

Other manufacturing and production services:

- Supports secondary processes including pad printing, sonic welding, foam-in-place gasketing, and tape-and-reel packaging.

- Offers technical engineering support from concept through production, including CAD review, process optimization, and quality system support (ISO 9001, IATF 16949, ITAR compliance)

9. Murray Plastics

Year founded: 1998

Location: Gainesville, Georgia, USA

Murray Plastics provides domestic custom injection molding services, including part design, tooling development, prototyping, and full production from a single facility. They collaborate with clients from early-stage sketches or CAD models through fulfillment and distribution.

The company operates a full in-house tool shop to build, maintain, and modify molds and supports materials such as ABS, nylon, polycarbonate, polystyrene, and HDPE/LDPE. They serve markets including electronics, packaging, industrial, and welding applications, accommodating volumes from small prototypes to millions of parts.

Injection molding solutions:

- Offers insert molding and standard injection molding across a range of plastic materials, serving both low-volume and high-volume needs.

- Supports prototype tooling and production tooling from 3D or 2D CAD input, with rapid turn timelines and inspection protocols including visual and functional testing.

Other manufacturing and production services:

- Provides part design and engineering support using tools like SolidWorks CAD and Mastercam, alongside prototyping via 3D printing.

- Delivers secondary operations such as ultrasonic welding, assembly, surface finishing, bar-code labeling, packaging, and fulfillment services.

- Manages inventory, warehousing, and distribution support for ongoing order flexibility and streamlined logistics.

10. MSI Mold

Year founded: 2005

Location: Almont Ave, Imlay City, MI

MSI Mold provides custom injection molding and precision CNC machining services from a single U.S.-based facility. They handle projects from part design and tooling through mold production, molding, and final delivery.

They cater to production volumes ranging from 100 to 100,000 parts per order and offer rapid prototype tooling with U.S.-made molds covered by a lifetime warranty if maintained on-site.

Their quality process includes advanced quality planning (AQP) and in‑house CMM inspection, with all molds and parts manufactured domestically for single-source control.

Injection molding solutions:

- Custom plastic injection molding

- Prototype injection molding

- Short-run and low-volume molding

- Engineering changes and mold trials

- Tight-tolerance molded parts

Other manufacturing and production services:

- Plastic mold manufacturing

- CNC machining (high-precision, 4-axis horizontal with pallet changer)

- CMM inspection (climate controlled)

- Engineering and tooling consultation

- Tooling program management

11. The Rodon Group

Year founded: 1956

Location: Hatfield, Pennsylvania, USA

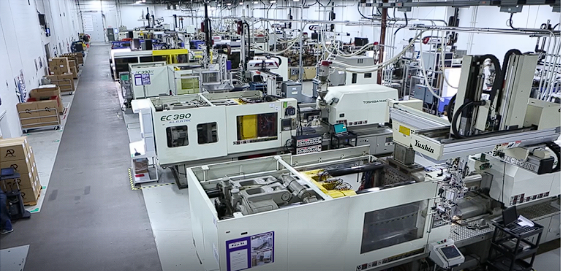

The Rodon Group operates a U.S.-based facility spanning approximately 125,000 sq ft, running over 125 injection molding presses. It is family‑owned and certified to ISO 9001:2015 (and ISO 13485), serving domestic production needs without offshore sourcing.

It collaborates on projects ranging from design and tooling to molding, fulfillment, and packaging, with over six decades of experience in high-volume precision manufacturing. The company supports markets including medical/pharmaceutical, food and beverage, window and door, consumer products, and construction.

Injection molding solutions:

- Supports cleanroom molding capabilities for regulated industries such as medical, pharmaceutical, and food & beverage.

Other manufacturing and production services:

- Offers turnkey services from design and engineering through tooling, molding, fulfillment, packaging, and order management.

- Maintains inventory and fulfillment via just-in-time programs, safety stock, and robotic packing systems to reduce freight costs and lead times.

- Manages mold lifecycle, repair, and refurbishment in-house, and operates a landfill‑free facility with ongoing sustainability initiatives.

12. Xometry

Year founded: 2013

Location: North Bethesda / Gaithersburg, Maryland, USA

Xometry operates an AI-driven online marketplace that connects buyers with a vetted network of manufacturers, rather than producing parts in its own facilities. It handles quoting, engineering evaluation, quality assurance, and project management centrally, while relying on external partners for actual manufacturing.

Its platform supports a wide array of fabrication methods, including injection molding, CNC machining, 3D printing, sheet metal, and more, with certifications such as ISO 9001:2015, ISO 13485, AS9100D, and IATF 16949.

Xometry does not operate molding presses internally; all molding work is performed by external suppliers selected via its AI matching system.

Injection molding solutions:

- Offers custom injection molding via its partner network, covering rapid prototyping and high-volume production.

- Provides immediate engineering review and DFM guidance during quoting and project execution, with lead times starting around five business days.

Other manufacturing and production services:

- Offers sourcing and fulfillment of secondary services via partner network: assembly, weldments, kitting, and electromechanical builds coordinated by Xometry.

- Manages quality assurance centrally, implementing standardized protocols across suppliers with features such as PPAP, custom inspection reports, CMM inspection, and certificates of conformance.

- Provides digital instant quoting, pricing, and lead time comparisons across manufacturing facilities.

What to Consider When Choosing an Injection Molding Company

- Experience and reputation: Choose a company with a strong track record of handling a variety of molding projects. Look for client feedback, case studies, and experience in your specific industry.

- Production capacity and capabilities: Evaluate whether the supplier can meet your volume needs, from low to high runs. Check for the right mix of equipment and production technologies to support part quality and throughput.

- Quality control: Ensure there are documented quality inspection procedures and defined tolerances. Ask about certifications and defect rates to assess process reliability.

- Material expertise: Verify that the supplier offers production-grade materials suited to your application. Check if they stock common resins and can work with customer-supplied materials if needed.

- Cost and lead times: Ask for detailed quotes with breakdowns for tooling, production, and delivery. Compare turnaround times across tooling classes to ensure alignment with your project timeline.

- Design and prototyping: Find out if the supplier offers design-for-manufacturing reviews before production. Access to prototyping and early design input helps reduce rework and cost.

- Communication and collaboration: Look for clear communication during quoting, design, and production. Dedicated support improves planning, issue resolution, and project execution.

- Tooling flexibility: Work with a provider that offers tooling options across Class 105 to Class 101, depending on your part volume and tool life needs. This allows you to start with rapid prototypes and scale up without switching vendors.

- Advanced part geometry: Confirm whether the company can mold complex or unrestricted geometries. Tooling capabilities should support tight tolerances and integrated features such as hand loads or inserts.

- Inspection accuracy: Check that part and tool tolerances are documented, not just estimated. Some vendors offer tolerances down to ±0.07 mm, with clear shrink rate calculations.

- Multi-phase production support: Select a supplier that can transition your part from prototype to production. This eliminates revalidation and reduces the time to market.

- In-house tooling and molding: Prioritize companies with in-house tool design and production. This provides better control over cost, timing, and engineering feedback throughout the project.

- Regional manufacturing presence: Consider suppliers with facilities in your region to avoid import delays and reduce freight costs. Local production also supports faster communication and easier coordination.

Partner with the Best Injection Molding Company in the US

Choosing a manufacturing partner that handles everything from prototype tooling to scaled production under consistent quality standards reduces risk and delivery delays. Prioritize suppliers that provide engineering support, clear inspection protocols, and scalable material options.

Quickparts supports tooling classes from Class 105 (prototype-grade) to Class 103 (production-grade), with mold materials ranging from aluminum to tool steel and part dimensions up to 1524 mm in length. Prototype parts can ship in as little as one week, and production molds typically deliver in two to four weeks, with tooling tolerances around ±0.07 mm depending on size and mold type.

Quickparts accepts part designs via its QuickQuote platform and includes free design for manufacturability analysis with each quote. The service supports a broad selection of production-grade plastics, tight tolerances, insert molding, overmolding, and multi-cavity tooling, all managed through its US facility and global, vetted partner network.

You can submit your CAD files through QuickQuote to get started on your custom quote with lead-time estimates and material selection options.

Ready to create your prototype or start production?

Get your free quote with Quickparts today!

Injection Molding Company FAQs

Which company is best for injection molding?

The best company for injection molding depends on your project needs, including part geometry, tooling speed, production volume, and inspection requirements. A company that supports rapid molding, guarantees part accuracy, offers multiple material options, and provides full tooling and production support, like Quickparts, allows you to meet those needs efficiently.

Quickparts supports multiple production phases, from prototyping to high-volume runs, using tooling classes matched to your part requirements. Their in-house teams provide design-for-manufacturing reviews, regional production, and defined timelines, with parts shipping in as little as one week.

What is the largest injection molding company in the world?

The largest injection molding company by revenue and production scale varies by year and industry segment. Many operate internationally, serving automotive, consumer, and industrial markets through global production networks.

Which country is best for injection molding?

Several countries lead in injection molding based on infrastructure, technology, and supply chain reliability. The United States remains competitive due to local production capacity, fast lead times, and reduced shipping risk for domestic customers.