Vacuum Casting/Cast Urethane casting with Quickparts

The Ultimate Quick Vacuum Casting Materials Guide

An overview of the mechanical and physical properties of Vacuum Casting or Cast Urethane polymer and elastomeric materials run by Quickparts

Quickparts Cast Urethane services, also known as Vacuum Casting, offers high-precision, producing parts that accurately mimic the color, texture, feel and physical properties of injection molded parts.

This Urethane Casting materials overview provides you with brief details on the mechanical and physical properties of the materials available, and access to the relevant technical data sheets to enable you to make the transition from design to prototyping and then real-world applications seamlessly.

Cast Urethane Materials

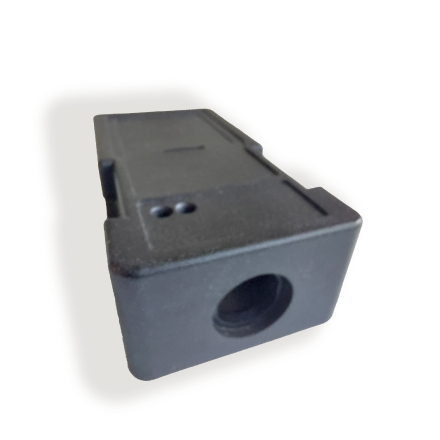

General Purpose (ABS-like)

For internal and non-cosmetic designs. Parts will have some build lines evident on outside of part and almost all on internal surfaces.

Ultimate Tensile Strength (MPa | PSI)

52 | 7600

Heat Deflection Temperature (˚C | ˚F)

90 | 195(at 0.45MPa)

Elongation at Break

10%

Impact Strength (Notched) (J/m | ft-lb/in)

37.4 | 0.7

Tensile Modulus (MPa | KSI)

1654 | 240

Polyethylene-Like

Tough, RoHS compliant, non-mercury-based Shore D polyurethane. Typical applications include parts requiring high heat and high heat deflection.

Ultimate Tensile Strength (MPa | PSI)

23 | 3310

Heat Deflection Temperature (˚C | ˚F)

116 | 240 (at 0.45MPa)

Elongation at Break

28.3%

Impact Strength (Notched) (J/m | ft-lb/in)

95| 1.78

Tensile Modulus (MPa | KSI)

491 | 71.35

Polypropylene-Like

For cosmetic and appearance parts. Build lines removed from external surfaces and reduced significantly on internal surfaces.

Ultimate Tensile Strength (MPa | PSI)

35 | 5076

Heat Deflection Temperature (˚C | ˚F)

100| 212 (at 0.45 MPa)

Elongation at Break

11%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

2068 | 155

Elastomer

Translucent Shore A polyurethane that is RoHS/Reach compliant and easy to pigment.

Ultimate Tensile Strength (MPa | PSI)

15 | 2100

Heat Deflection Temperature (˚C | ˚F)

N/A

Elongation at Break

415%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

4000 | 5.7

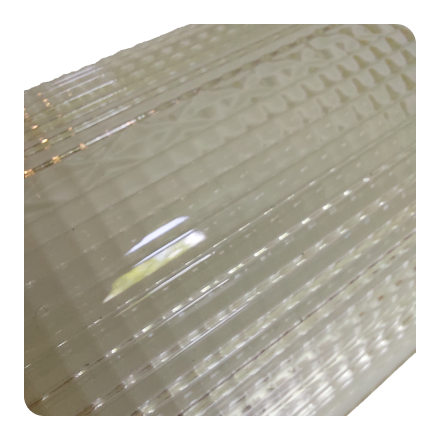

Clear Transparent

Water-clear Shore D polyurethane featuring excellent buffing and polishing characteristics. Perfect for automotive lenses and light pipes, housings for fluid testing equipment, amusement park props, and artistic jewelry.

Ultimate Tensile Strength (MPa | PSI)

72 | 10500

Heat Deflection Temperature (˚C | ˚F)

95 | 203 (at 0.45 MPa)

Elongation at Break

8%

Impact Strength (Notched) (J/m | ft-lb/in)

58.7| 1.1

Tensile Modulus (MPa | KSI)

1827 | 265

High Strength

Extremely stiff, high impact, translucent Shore D material that is RoHS compliant.

Ultimate Tensile Strength (MPa | PSI)

70 | 10060

Heat Deflection Temperature (˚C | ˚F)

88 | 190 (at 0.45 MPa)

Elongation at Break

10.5%

Impact Strength (Notched) (J/m | ft-lb/in)

60.9 | 1.14

Tensile Modulus (MPa | KSI)

2275 | 330

High-Temp (ABS-Like)

RoHS compliant, non-mercury-based Shore D polyurethane. Ideal for parts requiring high heat deflection temperatures

Ultimate Tensile Strength (MPa | PSI)

71 | 10300

Heat Deflection Temperature (˚C | ˚F)

171 | 340 (at 0.45 MPa)

Elongation at Break

9.1%

Impact Strength (Notched) (J/m | ft-lb/in)

47 | .88

Tensile Modulus (MPa | KSI)

2020 | 293