CNC machining with Quickparts

The Ultimate Quick CNC Materials Guide

An overview of the mechanical and physical properties of CNC materials offered by Quickparts

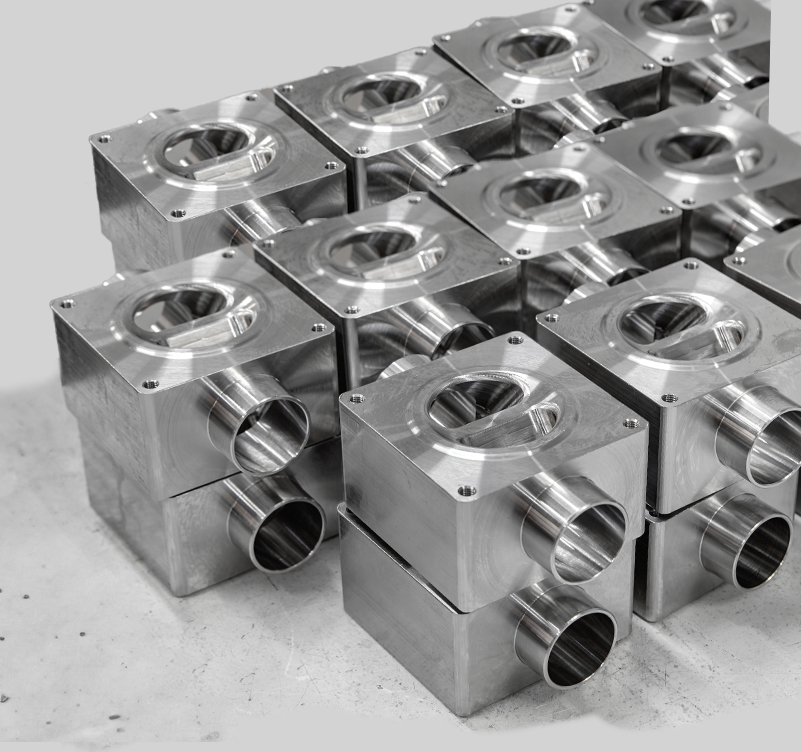

Quickparts CNC Services offers high-precision CNC, delivering ultra-fast production of parts with options for both metal and plastic materials.

This CNC materials overview provides you with brief details on the mechanical and physical properties of the materials, and access to the relevant technical data sheets to enable you to make the transition from design to prototyping and then real-world applications seamlessly.

CNC Materials

Aluminum 6061

Widely used in CNC machining for its excellent machinability, Aluminum 6061 offers high strength, good corrosion resistance, and weldability, making it suitable for aerospace components and automotive parts.

Ultimate Tensile Strength (MPa | PSI)

310 | 45000

Melting Point (˚C | ˚F)

625 | 1057

Machinability

450%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Aluminum 7075

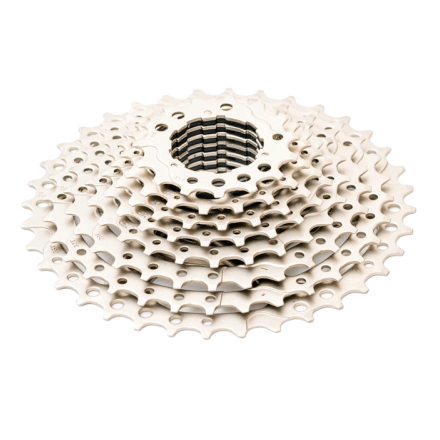

Renowned for its exceptional strength-to-weight ratio, Aluminum 7075 is favored in CNC machining for applications requiring high strength and low weight, such as aircraft structures and high-performance bicycle components.

Ultimate Tensile Strength (MPa | PSI)

572 | 83000

Melting Point (˚C | ˚F)

550 | 1022

Machinability

450%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Aluminum 2024

Recognized for its high strength and excellent fatigue resistance, Aluminum 2024 finds applications in CNC machining for aerospace components, structural parts, and high-stress applications where strength and durability are crucial.

Ultimate Tensile Strength (MPa | PSI)

469 | 68000

Melting Point (˚C | ˚F)

550 | 1022

Machinability

450%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Aluminum 6063

Valued for its good formability, excellent corrosion resistance, and smooth surface finish, Aluminum 6063 is often used in CNC machining for architectural and structural applications, as well as in the production of complex extrusions and automotive parts.

Ultimate Tensile Strength (MPa | PSI)

186 | 27000

Melting Point (˚C | ˚F)

625 | 1157

Machinability

450%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Stainless Steel 301

With its high strength, excellent corrosion resistance, and good ductility, Stainless Steel 301 is utilized in CNC machining for applications such as springs, washers, and fasteners in environments where corrosion resistance is essential.

Ultimate Tensile Strength (MPa | PSI)

15 | 74700

Melting Point (˚C | ˚F)

2650 | 4802

Machinability

45%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Stainless Steel 302

Stainless Steel 302 offers good corrosion resistance and moderate strength, making it suitable for CNC machining applications in the medical, automotive, and aerospace industries where a combination of corrosion resistance and affordability is required.

Ultimate Tensile Strength (MPa | PSI)

585 | 84800

Melting Point (˚C | ˚F)

1400 | 2550

Machinability

45%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Stainless Steel 303

Featuring enhanced machinability compared to other stainless steels, Stainless Steel 303 is commonly used in CNC machining for applications requiring excellent machining characteristics, such as fittings, shafts, and valves..

Ultimate Tensile Strength (MPa | PSI)

620 | 89900

Melting Point (˚C | ˚F)

1400 | 2550

Machinability

78%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Stainless Steel 304

Renowned for its corrosion resistance and ease of fabrication, Stainless Steel 304 is widely used in CNC machining for applications ranging from food processing equipment to architectural components and chemical processing machinery.

Ultimate Tensile Strength (MPa | PSI)

505 | 73200

Melting Point (˚C | ˚F)

1400 | 2550

Machinability

45%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Stainless Steel 316

Highly corrosion-resistant and offering excellent mechanical properties even at high temperatures, Stainless Steel 316 is favored in CNC machining for marine equipment, chemical processing plants, and medical devices where superior corrosion resistance is crucial.

Ultimate Tensile Strength (MPa | PSI)

550 | 79800

Melting Point (˚C | ˚F)

1370 | 2500

Machinability

45%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Stainless Steel 420

Known for its high hardness, good corrosion resistance, and excellent wear resistance, Stainless Steel 420 is utilized in CNC machining for manufacturing components such as surgical instruments, cutting tools, and molds.

Ultimate Tensile Strength (MPa | PSI)

660 | 95700

Melting Point (˚C | ˚F)

1455 | 2651

Machinability

45%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Stainless Steel 17-4 PH

Offering a unique combination of high strength, good corrosion resistance, and excellent mechanical properties, Stainless Steel 17-4 PH is commonly employed in CNC machining for aerospace components, nuclear reactor parts, and high-performance shafts and gears.

Ultimate Tensile Strength (MPa | PSI)

1103 | 160000

Melting Point (˚C | ˚F)

1400 | 2552

Machinability

48%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Steel 1018

A low-carbon steel with good weldability, machinability, and case hardening properties, Steel 1018 is frequently used in CNC machining for a wide range of applications including gears, shafts, and structural components.

Ultimate Tensile Strength (MPa | PSI)

440 | 63800

Melting Point (˚C | ˚F)

1421 | 2590

Machinability

78%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Steel 4130

Known for its high strength-to-weight ratio and excellent weldability, Steel 4130 is favored in CNC machining for applications such as aircraft components, bicycle frames, and automotive parts where strength and durability are critical.

Ultimate Tensile Strength (MPa | PSI)

670 | 97200

Melting Point (˚C | ˚F)

1421 | 2590

Machinability

72%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Steel 4340

Offering superior strength, toughness, and wear resistance, Steel 4340 is commonly used in CNC machining for applications such as aircraft landing gear, crankshafts, and structural components requiring high strength and durability.

Ultimate Tensile Strength (MPa | PSI)

1282 | 185900

Melting Point (˚C | ˚F)

1426 | 2600

Machinability

57%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Brass

Known for its excellent machinability, corrosion resistance, and attractive appearance, Brass is frequently used in CNC machining for producing decorative fittings, electrical components, and precision instruments.

Ultimate Tensile Strength (MPa | PSI)

400 | 58015

Melting Point (˚C | ˚F)

926 | 1700

Machinability

100%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Bronze

Featuring good wear resistance, high strength, and excellent thermal conductivity, Bronze is utilized in CNC machining for applications such as bearings, bushings, and marine hardware where a combination of strength and wear resistance is essential.

Ultimate Tensile Strength (MPa | PSI)

81 | 11750

Melting Point (˚C | ˚F)

926 | 1700

Machinability

38%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Copper

Valued for its high electrical and thermal conductivity, as well as its corrosion resistance, Copper is commonly used in CNC machining for electrical components, heat exchangers, and plumbing fittings.

Ultimate Tensile Strength (MPa | PSI)

210 | 30500

Melting Point (˚C | ˚F)

1085 | 1984

Machinability

30%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Zinc

Recognized for its low melting point, excellent casting properties, and corrosion resistance, Zinc is utilized in CNC machining for producing intricate die-cast components such as automotive parts, door handles, and architectural hardware.

Ultimate Tensile Strength (MPa | PSI)

37 | 5370

Melting Point (˚C | ˚F)

89 | 192 (at 0.45 MPa)

Machinability

100%

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

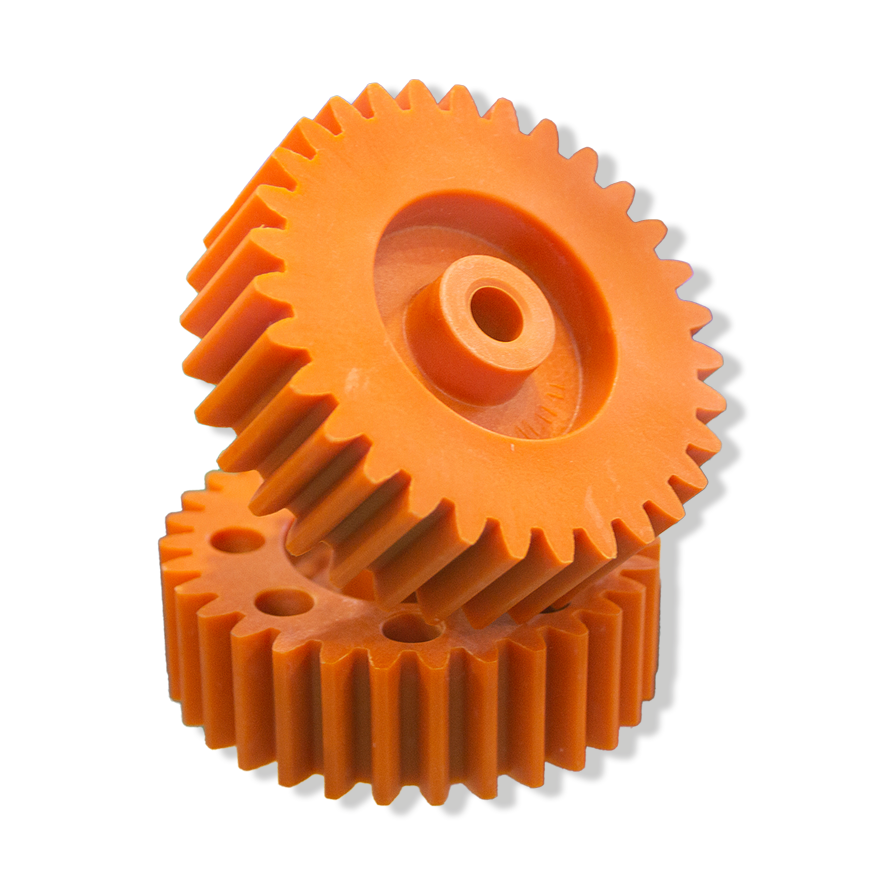

Acetal

Known for its excellent dimensional stability, low friction, and high stiffness, Acetal is often used in CNC machining for precision engineering components, gears, and bushings requiring tight tolerances and resistance to wear and moisture.

Ultimate Tensile Strength (MPa | PSI)

50 | 6000

Melting Point (˚C | ˚F)

82 | 180

Machinability

N/A

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

ABS

Recognized for its high impact strength, good machinability, and affordability, ABS is commonly utilized in CNC machining for prototypes, casings, enclosures, and consumer products requiring a balance of strength and cost-effectiveness.

Ultimate Tensile Strength (MPa | PSI)

35 | 5000

Melting Point (˚C | ˚F)

60 | 140

Machinability

N/A

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Nylon

Renowned for its high strength, toughness, and excellent wear resistance, Nylon is widely used in CNC machining for gears, bearings, rollers, and structural components requiring resilience to impact and abrasion.

Ultimate Tensile Strength (MPa | PSI)

Melting Point (˚C | ˚F)

Machinability

Impact Strength (Notched) (J/m | ft-lb/in)

Tensile Modulus (MPa | KSI)

Glass-Filled Nylon

Combining the properties of Nylon with added stiffness and strength due to glass fiber reinforcement, Glass Filled Nylon 30% is ideal for CNC machining applications requiring enhanced mechanical properties such as structural components, housings, and machinery parts.

Ultimate Tensile Strength (MPa | PSI)

90 | 13000

Melting Point (˚C | ˚F))

254 | 489

Machinability

N/A

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

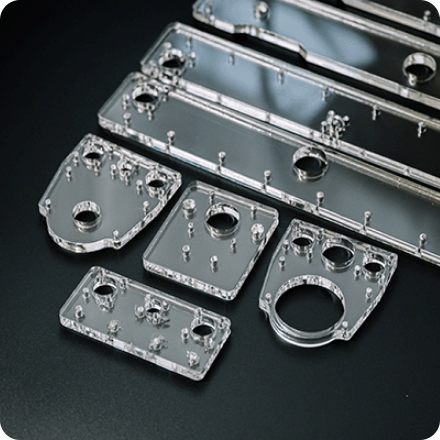

Polycarbonate

Valued for its exceptional impact resistance, transparency, and heat resistance, Polycarbonate is commonly employed in CNC machining for safety equipment, transparent enclosures, lenses, and high-performance components requiring clarity and durability.

Ultimate Tensile Strength (MPa | PSI)

55 | 8000

Melting Point (˚C | ˚F)

66 | 148

Machinability

N/A

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

Polypropylene

Known for its low density, chemical resistance, and affordability, Polypropylene is frequently used in CNC machining for packaging, fluid handling components, automotive parts, and consumer goods where a balance of strength and cost-effectiveness is required.

Ultimate Tensile Strength (MPa | PSI)

32 | 4500

Melting Point (˚C | ˚F)

66 | 150

Machinability

N/A

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

PEI (Ultem 1000)

With outstanding mechanical properties at elevated temperatures, exceptional strength, and excellent chemical resistance, PEI (Ultem 1000) is highly sought after in CNC machining for aerospace components, semiconductor equipment, medical devices, and automotive parts where performance in harsh environments and stringent regulatory compliance are paramount.

Ultimate Tensile Strength (MPa | PSI)

115 | 16700

Melting Point (˚C | ˚F)

343 | 649

Machinability

N/A

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

HDPE

Offering excellent chemical resistance, low moisture absorption, and ease of machining, HDPE is favored in CNC machining for food processing equipment, chemical tanks, conveyor components, and marine applications where durability and corrosion resistance are essential.

Ultimate Tensile Strength (MPa | PSI)

38 | 5300

Melting Point (˚C | ˚F)

126 | 259

Machinability

N/A

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

UHMW-PE

Recognized for its extremely low friction coefficient, high impact strength, and excellent wear resistance, UHMW-PE is ideal for CNC machining applications such as conveyor guides, wear strips, bushings, and sliding components in harsh environments.

Ultimate Tensile Strength (MPa | PSI)

40 | 5800

Melting Point (˚C | ˚F)

137 | 278

Machinability

N/A

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A

PEEK

Known for its exceptional mechanical properties at high temperatures, chemical resistance, and dimensional stability, Peek is commonly used in CNC machining for aerospace components, medical implants, automotive parts, and electrical insulation where performance under extreme conditions is crucial.

Ultimate Tensile Strength (MPa | PSI)

100 | 14000

Melting Point (˚C | ˚F)

343| 662

Machinability

N/A

Impact Strength (Notched) (J/m | ft-lb/in)

N/A

Tensile Modulus (MPa | KSI)

N/A