Injection molding is a forming process using molds. Plastic materials are heated and melted, and then pushed (injected) into the mold where they are cooled to form the desired shape (that of the mold).

With injection molding, parts with diverse geometries, including those with complex shapes, can be quickly and continuously manufactured in large volumes. Injection molding is used to manufacture products in a wide range of industries and encompasses commodity items as well as precise engineering components.

Injection Molding Process

Typically, injection molding begins with resin pellets (granules) that get poured into a hopper, the entry point for the material. The pellets are then heated and melted inside the cylinder in preparation for injecting them into the mold. The material is then forced through the nozzle of the injection unit before being delivered through a channel in the mold called a sprue, then through the runners/gate into the mold cavity. After the material cools and hardens, the mold opens, and the molded part is ejected from the mold. The sprue and runner are trimmed from the part.

Injection Molding Machine

The structure of an injection molding machine consists of an injection unit that sends the melted materials into the mold and a clamping unit that operates the mold.

There are different types of injection molding machines. That is, machines operated by servo motors, those operated by hydraulic motors, and hybrid machines that use both servo and a hydraulic motor.

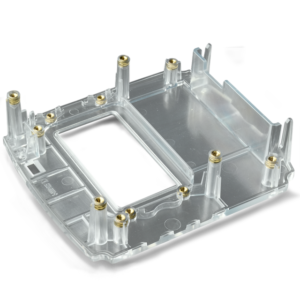

After an engineer designs a product, molds are made by a mold-maker (or toolmaker) from metal, usually either steel or aluminum, through precision machining to form the features of the desired part.

Parts created for injection molding must be designed carefully to facilitate the molding process; the material used for the part, the part’s desired shape and features, the mold material, and the properties of the molding machine must all be considered during the design phase. The versatility of injection molding process is facilitated by this breadth of design considerations and possibilities.

Read more about Designing for Injection Molding here.

If you’re looking for a partner in additive or traditional manufacturing, check out our capabilities today. We can help keep your projects moving forward – begin a quote now or contact an expert.