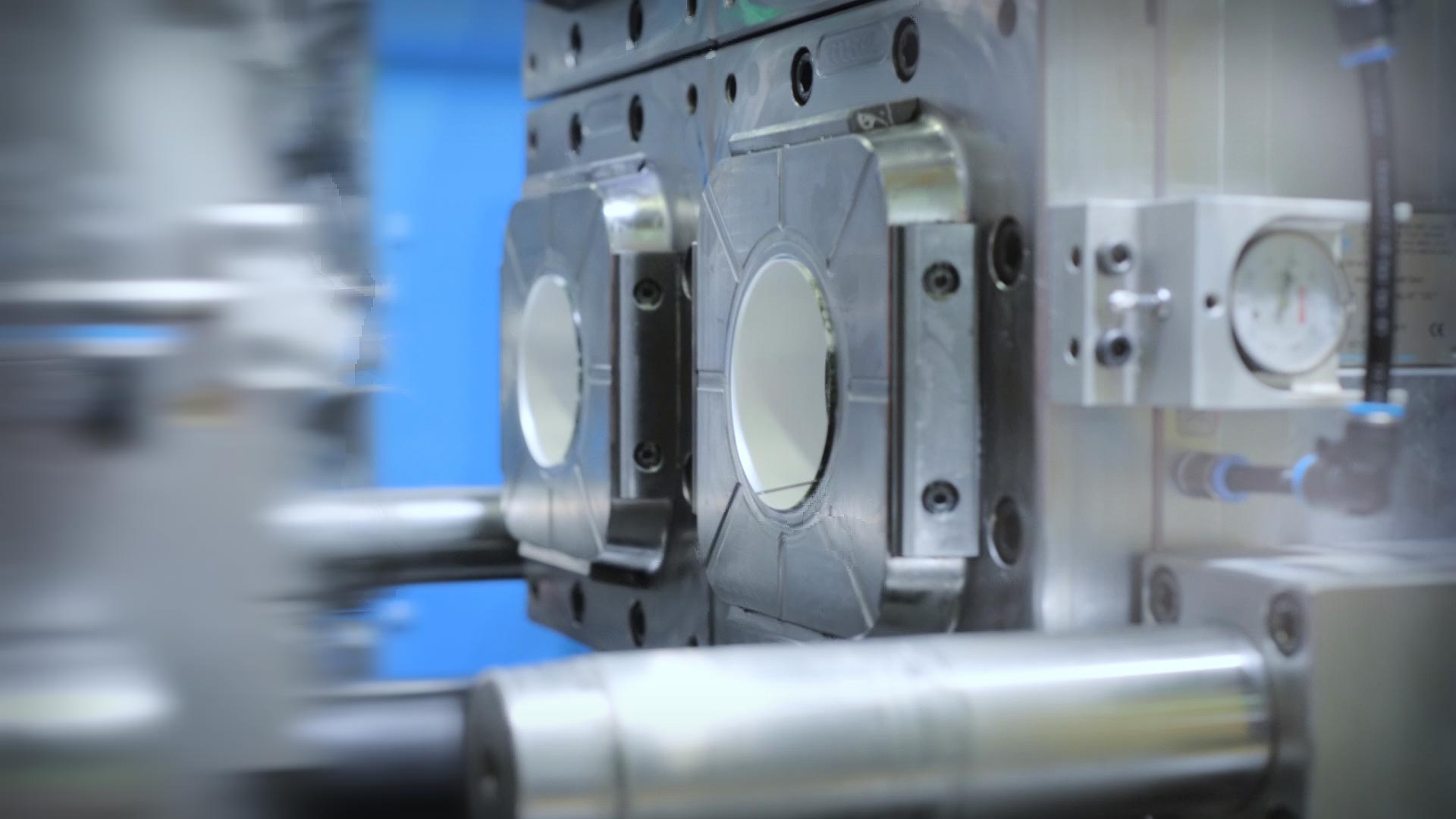

Our Injection Molding Solutions

Quickparts’ plastic Injection Molding services offer a comprehensive suite of solutions, catering to diverse project requirements ranging from rapid prototyping for swift design validation, up to volume production runs, accommodating geometrically complex parts.

With 25 years of experience and an in-house network of manufacturing facilities, we specialize in injection molding—the optimal method for cost-effective mass production of plastic parts. Our process ensures consistent quality across low-to-high-volume manufacturing needs. Click on the headings for more information.

Quick Molded Parts |

Prototyping |

Production |

|

|

|

As a qualified Injection Molding supplier, we offer a range of advanced techniques, including:

- Overmolding: Enables creation of multi-material components with distinct properties.

- Stack Molding: Produces multi-level injection molded parts through stacked mold faces.

- Hot Runner Moulds: Optimizes cycle times and minimises material waste.

- Insert Moulding: Integrates metal or other inserts for enhanced strength or functionality.

- Highly Intricate Tooling: Produces parts with complex geometries and tight tolerances.

- Multi-Cavitation Tooling: Increases production efficiency by creating multiple parts per cycle.

ABOUT QUICKPARTS: One of the World’s Leading Injection Molding Suppliers

We are the originator of a full digital manufacturing platform that delivers on-demand additive and traditional manufacturing services. From rapid prototyping to appearance models and volume production, Quickparts operates the most advanced technology and possesses the expertise to handle most manufacturing projects.

With facilities stationed around the world, each staffed with experienced engineers laser-focused on meeting your specific requirements as effectively and quickly as possible, you can trust Quickparts as one of the premier suppliers with all of your manufacturing needs.

We have a streamlined approach to mold making, plastic Injection moulding, and engineering processes. We have a separate team of quality control specialists who understand the importance of value, quality, and consistency in moulded products. This is how we can differentiate ourselves from our competitors.