Utilizing the latest Plastic Jet Printing machines, Quickparts provided Magellan Tech with durable prototypes of the MDocR-2505 in a variety of colors for fit and function testing. All parts were shipped via FedEx International Priority to ensure safe shipping conditions and earliest arrival.

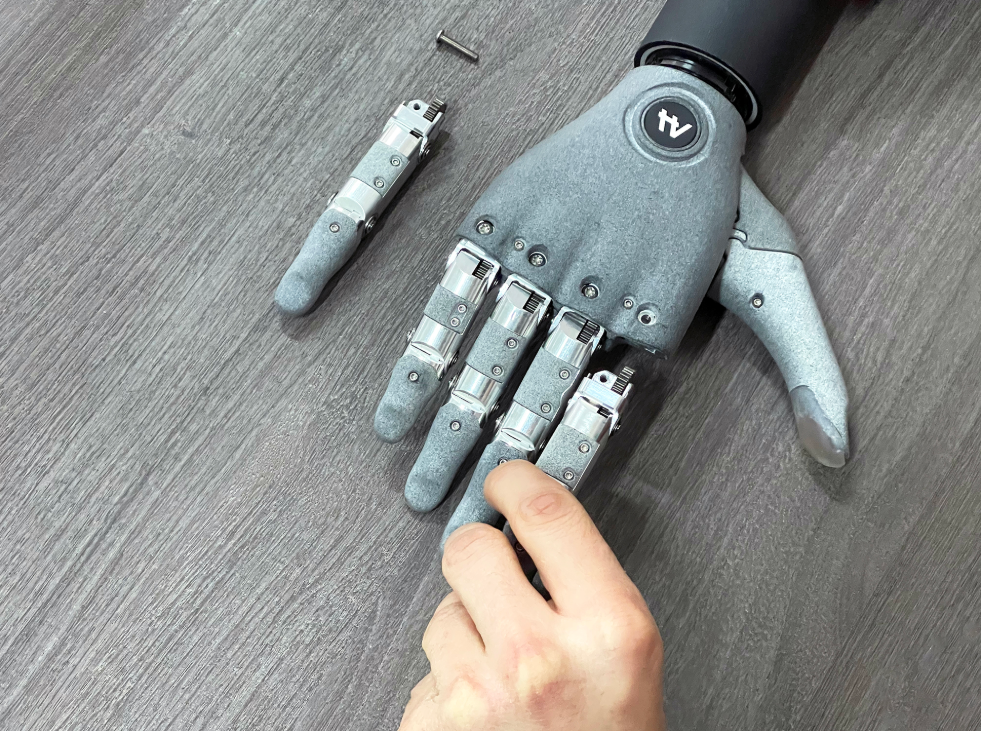

As the design was finalized through multiple iterations, Quickparts built production-quality display models through the QuickPlastic™ Cast Urethane/RTV mold process to allow Magellan to demonstrate the electronic document management solution at International tradeshows.

Magellan launched the MDocR-2505 reader to an overwhelming response. Based upon customer feedback, the company is currently expanding its product line to include a heavy-duty stackable version and an executive lite version.