Digital Light Processing

Digital Light Processing unlocks the possibility of ultra-fast print speeds.

To get the most out of your project, however, you need expert operators, attentive project managers, and logistics that put the customer first.

Quickparts has all those factors and more. Our team of experienced engineers coupled with our well-equipped facilities stationed around the world allows us to support your Digital Light Processing projects wherever you are based.

How it Works

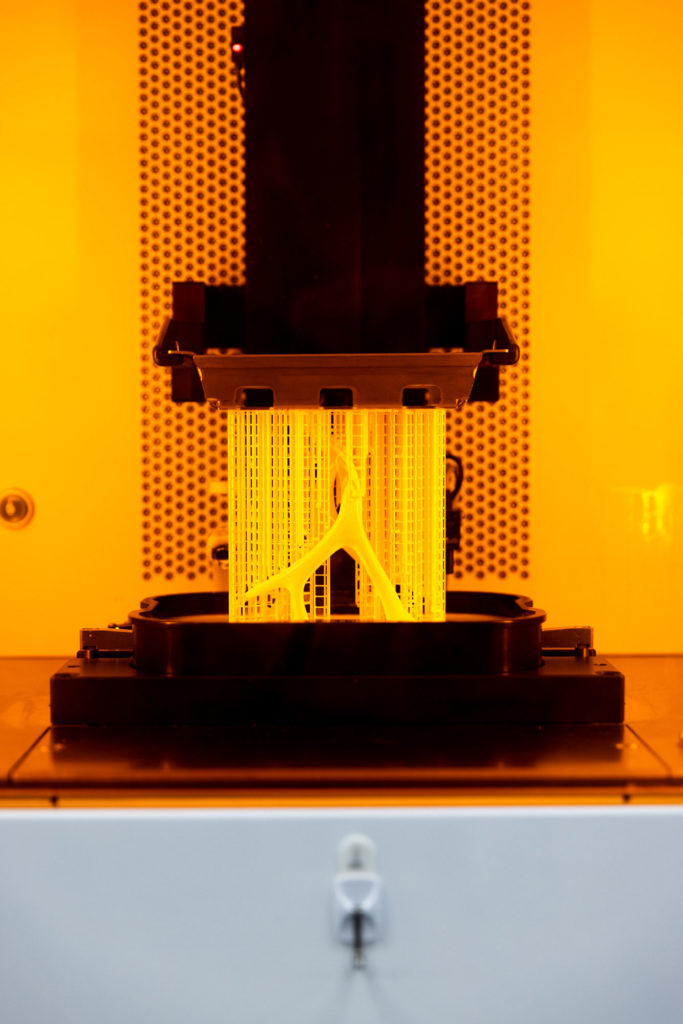

During Digital Light Processing, a vat of liquid polymer is exposed to light from a DLP projector under safelight conditions. An image of the 3D model is projected onto the liquid polymer, and the exposed polymer hardens.

This process continues layer by layer until the 3D model is complete.

Let us be your resource to determine which manufacturing process is right for your project.

About Quickparts

Quickparts is a pioneer in the 3D printing world.

We are the originator of a full digital manufacturing platform that delivers on-demand additive and traditional manufacturing services. From rapid prototyping to appearance models and volume production, Quickparts operates the most advanced technology and possesses the expertise to handle any additive manufacturing project.

With facilities stationed around the world, each staffed with experienced engineers laser-focused on meeting your specific requirements as effectively and quickly as possible, you can trust Quickparts with all of your manufacturing needs.

Get Started

You’re seconds away from starting your Quickparts project.

DLP Printing Service- We Have The Best 3D Printing Specialists

3D printing technology has become advantageous for manufacturers who need to use prototypes. At Quickparts, we are known for producing flawless photopolymer parts with the Digital Light Processing technique. We can cure layers and accomplish the DLP process with a projected light source from our DLP machine.

When do you need our DLP printing service?

Our Digital Light Processing 3D printing solutions are best for creating different items like

- Dental molds and medical devices

- Automotive parts

- Aerospace parts

- Visual prototypes

- Copies of vacuum casting

Are you choosing between DLP and SLA? Digital Light Processing (DLP) is faster when compared to SLA so if you need your part fast, DLP is the way to go.

What types of resin do we use for DLP printing?

We choose different types of resin for the 3D printing project-

- Standard resin- It creates a matte surface finish best for designing complicated components.

- Clear resin- We use the resin for optics, fluidics, lighting, and some other parts that need translucency.

- Tough resin- Due to its ABS-like properties, you can choose the resin for functional testing.

- Castable resin- We use resilient resin to print fine parts.

- Pro black- With high strength and durability, this resin is known for its surface quality.

- Rubber-like resin- We can stimulate rubber parts with this resin.

We are able to deal with different types of finishes based on the materials chosen for the DLP project. From silkscreen to painting, various finishes are compatible with plastics and metals.

How do we carry out DLP printing?

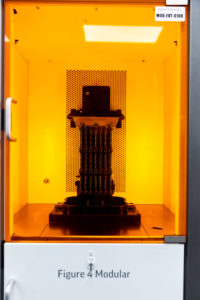

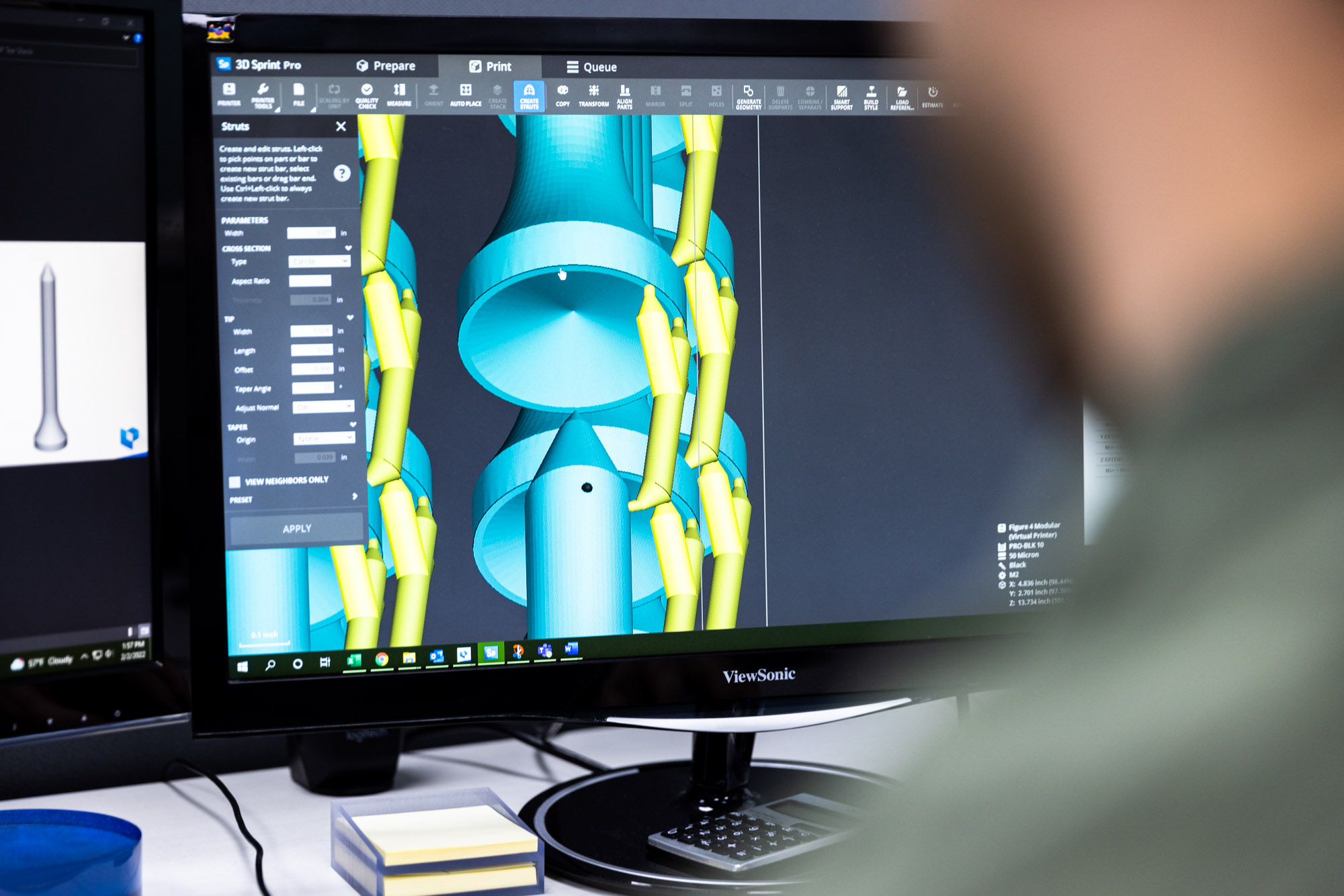

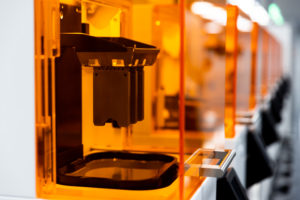

We have high-quality 3D printing machines to manage our DLP projects. Our printers accept CAD and STL files, which can be categorized into layers to prepare for printing.

We then submerge the build platform of the printer in a liquid resin. A source of light projects every layer onto it. This light facilitates the curing process of the resin and creates a solid silver.

We develop layers on top of each other and remove the part from the build platform.

DLP prints are known for resolution and accuracy. This is how we can help you with the DLP 3D printing service.

Why do our clients prefer DLP printing for 3D prototypes?

Our DLP printing machines provide you with the fastest solution. Moreover, we are efficient at maintaining accuracy in the layers. DLP ensures colorful, sharp, and clear contrast images. The gap between every micromirror is up to 1 micron. In fact, there is very limited space between pixels. That is why you will find a clearer image.

Are you ready to submit your project and get a quote for your DLP part? Click hereto get started!